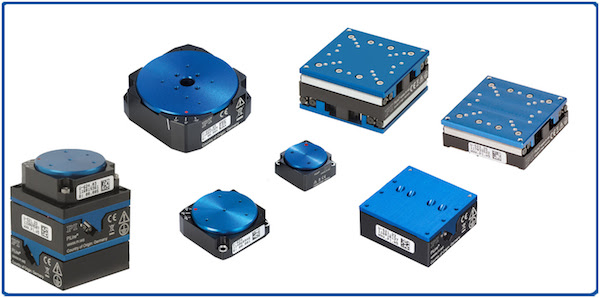

A new family of compact linear and rotary stages from PI (Physik Instrumente) is driven by ceramic direct-drive motors. The patented ultrasonic motors provide smooth motion with high resolution and a high dynamic range. The self-clamping motor principle locks the stage into place, devoid of creep, once a target position has been reached. This intrinsic brake-like behavior comes at no extra cost, and provides advantages that are not available with classical electro-magnetic drive technologies.

Two linear stages with 18 mm and 22 mm travel are available, as well as an XY stage with 22 x 22 mm travel. Several encoder options, from 0.4 µm to 10 nm, are standard. All stages achieve closed-loop peak velocities to 200 mm/sec. The rotary stages come with turn-table diameters from 20 to 50 mm, encoder resolution down to 17 µrad, and maximum velocity of 720 degrees/sec.

The low-inertia direct drive, with no gears and other mechanical components to convert motion, allows for a dynamic start-stop behavior with settling times in the millisecond range. Based on the ultrasonic principle with drive frequencies greater than 100 kHz – well beyond the human hearing range – the motors are silent. Displacement is generated in continuous sub-nanometric increments, leading to extremely smooth motion with a wide dynamic range.

Linear and rotary stages can be combined to form multi-axis combinations. Due to the high efficiency of the ultrasonic motors, the miniature stages can be integrated into mobile measuring and medical devices. Typical applications include medical devices, optical instrumentation, photonics alignment, and microscopy.

For more information, visit www.pi-usa.us.

Leave a Reply

You must be logged in to post a comment.