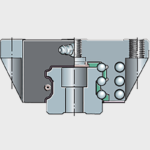

As a world leader in compact linear motion systems, Ametek Haydon Kerk Pittman (HKP), a business unit of Ametek, is pleased to announce its new EGS04 low-profile precision rail. The EGS “efficient guided system” is ideally suited for customers in lab automation and electronic assembly whose applications require high speed and highly efficient point-to-point motion. […]

Ball + roller guides

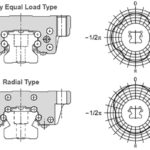

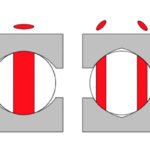

What are the benefits of six-row linear bearings

The most common types of recirculating linear bearings use four rows of balls — two on each side of the bearing block — to provide good load capacity and rigidity. But the four-row design means that when radial (downward or liftoff) or lateral (side) loads are applied, only two rows of balls are engaged to support […]

Contact angle: What is it and how does it affect linear bearing performance?

In profiled rail linear guides that use balls or rollers, the geometry and arrangement of the bearing raceways play a significant role in the bearing’s load capacity, friction, rigidity, and ability to withstand errors in mounting. But there’s another aspect of a bearing’s design that also plays a role in its load capacity and rigidity […]

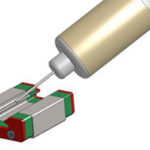

How to choose a lubricant for recirculating linear bearings

All metal-on-metal recirculating bearings require lubrication in order to function properly and provide a reasonable bearing life. Lubrication reduces friction and heat by separating the rolling elements from the bearing raceway, inhibits corrosion, protects bearing surfaces from contamination, and helps seals run smoothly and operate effectively. Although the importance of lubrication is clear, choosing the best […]

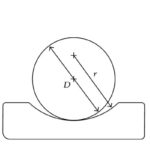

Motion basics: What is ball conformity in linear guides and screws?

In linear guides and ball screws, load-carrying balls or rollers can ride on planar (flat) raceways, as with non-recirculating linear roller bearings, or in curved raceways, as with ball screws and profiled rail guides. When a ball or roller rides on a planar raceway, the contact between the rolling element and the raceway will be […]

Motion basics: What is differential slip and how does it affect linear bearings?

Linear bearings that use balls or rollers are typically chosen for their ability to carry high loads with very low friction. But rolling elements — including linear bearings — are not friction-free. One of the factors that contributes to friction in linear bearings (along with properties such as surface roughness, elastic hysteresis of the materials, and […]

Mechanical properties of materials: Hardness

Hardness is a common specification for linear shafts and guides — especially those used with ball and roller bearings, where the guide encounters extremely high loads over very small areas. The hardness of a bearing surface can significantly affect the life of the system and is often accounted for by applying a hardness correction factor […]

What is cage creep and why does it matter?

Several types of non-recirculating linear bearings use a cage to contain the rolling elements, maintain consistent spacing between them, and ensure even load distribution. But in each of these non-recirculating designs, the cage “floats” between the two moving components, meaning that it’s not constrained and can gradually move away from its intended, centered position. This […]

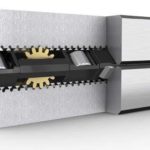

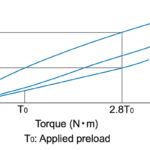

Ball spline preload: How, why, and when it’s applied

Like other linear motion components where rolling elements ride in raceways, ball splines can be supplied with preload. In the case of a ball spline, the main purpose of preload is to reduce angular backlash — clearance in the rotational direction — when torque is applied. Without preload, ball splines have a small amount of […]

Gothic arches, tracks, and roller bearings in the context of linear motion

Industry terminology used to describe linear guides and other linear components widely varies. Here we explain three linear-guide phrases and words having multiple meanings — and differentiate how they relate to track-roller linear guides and profiled-rail linear guides. Let’s start by reviewing the multiple linear-motion meanings for Gothic-arch linear bearing. Gothic arches originate from civil […]