In a recent case study, we detailed how cable-systems manufacturer HELUKABEL helped automate a vertical-farming installation: Cables satisfy the unique demands of vertical farming. In contrast with approaches to optimize the traditional farming of fields, automated greenhouses solutions eliminate issues associated with tight labor markets, guarding delicate or valuable crops, and the need to apply […]

Linear bearings

Extending the life of profile rail linear guides

Round rail linear guides can offer the lowest overall cost of ownership, but machine designers often specify profile-rail for its compactness as well as its higher rigidity, load capacity, and accuracy. Here’s how to extend the life of these linear-motion components. By Curtis McCreight • product line specialist | Thomson Industries Dave Buckley • industrial […]

Linear bearing from Rollon handles light-to-moderate loads in linear motion applications

Rollon has introduced its lightweight MiniRoller Rail linear bearing. Ideal for applications that require moderate loads, it features smooth and silent operation and an adaptive design that is easy to customize and integrate into assemblies. MiniRoller Rail eliminates the noise, difficult assembly, misalignment and unnecessary weight typically associated with using linear guides with recirculating ball […]

igus modular linear axis for travels of any length

igus, the Germany-based manufacturer of motion plastics, is launching the drylin Endless Gear linear module (EGW), a modular, lubrication-free linear guide with rack and pinion drive. The modular system can be extended to any travel length, costs little, and is almost as light as the guide for a toy train. Several carriages can travel on […]

Low-load polymer bushing bearings increase motion system design flexibility

Thomson Industries, Inc., has added a polymer bushing to its line of state-of-the-art Ball Bushing bearings. It expands the company’s extensive bearing portfolio, providing design engineers a new option that helps them avoid overdesigning for low-load applications. Thomson polymer bushing bearings provide a reliable solution for machines where moment load is non-critical (30 to 40 […]

Nook Industries sells family business to Altra Industrial Motion Corp.

Nook Industries, a leader in US engineered linear motion products and solutions, announced today that it has sold the family-owned business to Braintree, Massachusetts-based Altra Industrial Motion Corp. (Nasdaq: AIMC), a leading global manufacturer and supplier of motion control, power transmission and automation products. The Nook business, which will be integrated into Altra’s Thomson operating […]

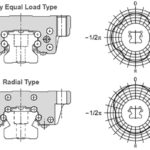

Contact angle: What is it and how does it affect linear bearing performance?

In profiled rail linear guides that use balls or rollers, the geometry and arrangement of the bearing raceways play a significant role in the bearing’s load capacity, friction, rigidity, and ability to withstand errors in mounting. But there’s another aspect of a bearing’s design that also plays a role in its load capacity and rigidity […]

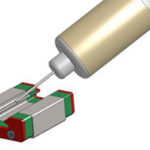

How to choose a lubricant for recirculating linear bearings

All metal-on-metal recirculating bearings require lubrication in order to function properly and provide a reasonable bearing life. Lubrication reduces friction and heat by separating the rolling elements from the bearing raceway, inhibits corrosion, protects bearing surfaces from contamination, and helps seals run smoothly and operate effectively. Although the importance of lubrication is clear, choosing the best […]

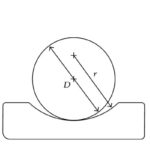

Motion basics: What is ball conformity in linear guides and screws?

In linear guides and ball screws, load-carrying balls or rollers can ride on planar (flat) raceways, as with non-recirculating linear roller bearings, or in curved raceways, as with ball screws and profiled rail guides. When a ball or roller rides on a planar raceway, the contact between the rolling element and the raceway will be […]

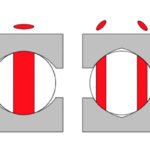

Motion basics: What is differential slip and how does it affect linear bearings?

Linear bearings that use balls or rollers are typically chosen for their ability to carry high loads with very low friction. But rolling elements — including linear bearings — are not friction-free. One of the factors that contributes to friction in linear bearings (along with properties such as surface roughness, elastic hysteresis of the materials, and […]