Automation over the last several years has expanded use of electric linear actuators to leverage their technological advancements in smart homes, aerospace, defense, and industrial applications. In fact, the global linear actuator market could (in large part because of electric options) surpass U.S. $52.67B this year and grow at a compound annual growth rate through […]

Packaging focus: Carton making and packing operations

Carton making and case packing are key operations in packaging facilities. Both rely on extremely fast motion systems with dozens of mechanically and programmatically linked axes for sufficient throughput to satisfy the demands of a global market. Case packing in particular is a common bottleneck. Typically, cartoners are installed at the ends of production lines, […]

Motion designs key to vertical farming

In a recent case study, we detailed how cable-systems manufacturer HELUKABEL helped automate a vertical-farming installation: Cables satisfy the unique demands of vertical farming. In contrast with approaches to optimize the traditional farming of fields, automated greenhouses solutions eliminate issues associated with tight labor markets, guarding delicate or valuable crops, and the need to apply […]

Extending the life of profile rail linear guides

Round rail linear guides can offer the lowest overall cost of ownership, but machine designers often specify profile-rail for its compactness as well as its higher rigidity, load capacity, and accuracy. Here’s how to extend the life of these linear-motion components. By Curtis McCreight • product line specialist | Thomson Industries Dave Buckley • industrial […]

New SX series Linear Shaft Motors boast greater power in mid-size package

Nippon Pulse now offers a new series of motors to its extensive line of Linear Shaft Motor servomotors. The SX series features high-energy magnets for greater force in mid-range sizes, to supplement the existing sizes of the standard S-series motors. The SX series motors are available in 6, 8 and 10mm shaft diameters. Each size […]

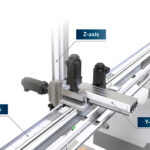

Simplifying overhead machine tending with long-travel automation

Cartesian robots with the right design upgrades can assume manual transfer operations. By Michael Everman • Founder and CTO | Bell-Everman Manufacturing and packaging operations using manual material or parts handling operations can reap immediate benefits from automation with long-travel Cartesian robots having custom end-of-arm tooling (EoAT) and advanced sensing capabilities. These robots can support […]

Track roller linear guides: Two needs for lubrication

Many track-roller linear guides necessitate lubrication at two different points in their assembly: Within the rolling-element rotary bearings at the heart of each track-roller wheel and Along the linear track-roller raceway. As with most any mechanical power-transmission devices, lubrication of these two critical areas extends the linear guide’s service life by minimizing or eliminating the […]

Ballscrew splines updated for 21st-century technological needs

The two types of ballscrew splines from NB Corp. are the SPBR and the SPBF. The SPBR type has a rotary ballscrew nut and rotary ball spline nut. The rotary ballscrew nut is an integration of ballscrew nut and angular contact bearings. The rotary ball spline nut is an integration of ball spline nut and […]

Mobile version of Gates Design Power now available

Gates just released a mobile version of Gates Design Power — a digital design tool to support the engineering of belt drive systems on customers’ mobile devices. “With the launch of Design Power Mobile, we’re demonstrating our ongoing commitment to accelerate our Chain to Belt initiative, driving the conversion of legacy drive technologies to clean, […]

Bosch Rexroth adds new BSCL Ball Rail to linear-guide portfolio

Bosch Rexroth now offers a new lineup of BSCL linear guides. The new BSCL ball rails address applications requiring linear bearings in the mid-performance range, and the new structural design delivers an optimum price to performance ratio. BSCL ball rails are available in five sizes, six runner block types, three preload classes and three accuracy classes. […]