Synchronous belt drives dominate motion control designs for positioning and other precision functions. Here we detail V belts and other belt types used in industrial, robotic, and consumer designs for both linear and rotary axes. Modern flat belts are either endless (welded or otherwise closed into a hoop by the manufacturer) or open. Common on […]

Belt + chain driven

Update on today’s belt drives

Belt drives have continued to evolve with new applications. Industrial belt drives in motion designs consist of rubber, engineered plastic, metal, or (most common) multi-material belts that wrap around drive pulleys — grooved or otherwise profiled wheels mounted on a shaft — in turn driven by electric motors. Powered by various motor types, belt drives run […]

Multi-axis transfer robot features backlash-free belt drive

Bell-Everman has introduced a new multi-axis transfer robot based on its proven ServoBelt backlash-free belt drive technology. Called ServoBelt Arc Drive, it features custom designed rotary and tilt axes that precisely position semiconductor glass panels. Measuring 450-mm across, the robot’s large rotary axis is built around a ServoBelt drive mechanism and a proprietary Bell-Everman bearing […]

igus offers custom toothed belt pulleys delivered in 48 hours

igus is expanding its 3D-print and online ordering offering to include custom format toothed belt pulleys. Toothed belt pulleys are a common component in many machines and are widely used in linear drives of printers, robots, and packaging machines. However, if an individual variant is required, developing a custom component can take days or even […]

Belt-driven linear actuators integrate seamlessly with industrial machines

Combining sturdy construction, protective features and high-performance characteristics for load, moment control, speed and acceleration, the Plus System family of belt-driven linear actuators from Rollon features an anodized aluminum structure and steel reinforced driving belt. All series are available with stainless steel elements for applications in harsh environments such as those subject to frequent washes. […]

Self-lubricating toothed belt axis for clean use in food manufacturing

igus has introduced a maintenance-free toothed belt axis specifically designed to improve sanitation in food manufacturing systems. The new drylin ZLW toothed belt axis is based on hygienic design principles and uses FDA-compliant materials. Cleaning complex machines and systems in food production leads to longer and therefore expensive downtime. For instance, industrial bakeries are faced […]

Belt-driven linear actuators feature greater load capacity

Rollon has updated its SMART SYSTEM lineup of belt-driven linear actuators with a rugged new design that supports heavy loads and ensures low maintenance operation in automated manufacturing, packaging machines and food and beverage equipment. The actuators have a self-sustaining anodized aluminum frame and a steel reinforced driving belt, and are engineered to provide stiffness […]

Causes of tooth shear in synchronous belts, and how to avoid it

Synchronous belts transmit power via positive engagement between belt teeth and pulley grooves, making them suitable for applications that require high torque and making them less prone than traditional V-belts to slip in dynamic applications. But even synchronous belts can experience failure if they’re not installed, maintained, and applied properly. One way that toothed belts […]

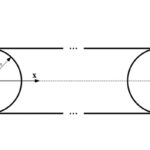

How to account for belt and pulley inertia during system design

In order for a motor to accelerate or decelerate a load, it must overcome the load’s inertia, or resistance to change in motion, as explained in Newton’s First Law. In belt-driven linear motion systems, the motor has to overcome not only the inertia of the applied load, but also the inertia of the belt, pulleys, […]

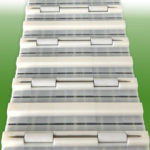

BRECOflex launches new BRECOroll timing belt

BRECOflex CO. is launching a new timing belt. It’s the company’s most innovative timing belt to hit the market since its move-series in 2014. It’s called BRECOroll. Typically, toothed timing belts used for material handling tasks are very long. The belt’s load side usually lies in a support rail which causes friction. BRECOroll provides the […]