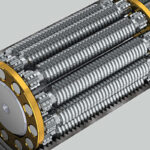

Thomson Industries, Inc. announces the availability of new German-engineered precision ball screw sizes with US-based distribution and machining that provide best-in-class load capacity in a small footprint. The Thomson miniature metric ball screw line uses a unique multi-start ball return design that maximizes support for higher loads. This design provides precise, smooth and quiet operation […]

Ball + leadscrew driven

Thomson debuts online product selector simplifying screw jack configuration, selection

Thomson has added a unique screw jack configuration and selection tool to its online engineering toolset. The new Thomson screw jack product selector helps design engineers optimize and specify screw jacks for applications involving loads of up to 100 tons. “Screw jacks are increasingly replacing hydraulic cylinders in many ultra-heavy, low duty-cycle applications, and there […]

Miniature lead screws for compact application designs

Thomson Industries, Inc., has introduced a line of miniature lead screws and nuts. This new offering extends the Thomson lead screw product line to include 2-, 3- and 4-millimeter diameters. “OEMs are increasingly demanding components for smaller assemblies, and we are pleased to announce that Thomson high-quality lead screws and nuts are now available in […]

IKO offers AutomationWare electric actuators for optimal positioning accuracy and control

IKO International has announced the U.S. availability of the Mech Series of E-actuators as part of its distribution partnership with AutomationWare. With AutomationWare’s Mech Series E-actuators, engineers can obtain accurate, controllable movement for almost any performance and size requirement. The series features an advanced ball screw transmission system to handle a wide range of dynamic […]

Lead-screw assemblies from igus for automotive applications

igus’ dryspin lead-screw assemblies are now available as a single-source solution for the automotive industry. In today’s vehicles, advanced linear motion components play a critical role in providing convenience and safety to drivers. Lead-screw assemblies are used extensively wherever automotive parts need to be opened, closed, lifted, or lowered. Typical uses include seats, doors, sunroofs, […]

What is a high helix (high lead) screw?

Ball and lead screws are specified by the diameter of the screw shaft and the lead (or, in some cases, pitch) of the screw thread. The lead, which specifies how far the nut travels for each revolution of the screw, is created by the thread, or helix, that wraps around the screw shaft. If the […]

Screw drives see new uses in robotics, other applications

Some of the surest, time-tested methods of linear actuation are screw drives. Whether lead- or ball- or roller screws, screw actuation remains a large part of the linear actuation equation, thanks to their reliability, accuracy, and relative simplicity of operation. Recently screw drive developments have included advances in materials as well as manufacturing methods leading […]

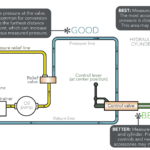

Part 2 of 2: Electric actuators as an alternative to hydraulic cylinders

Here we offer some tips for converting a fluid-power-driven axis to electrical actuation. By Ryan Klemetson • Business Development Manager | Tolomatic, Inc. As explained in Part 1 of this article series on motioncontroltips.com, hydraulic systems offer long service life, but they’re not as efficient as electric systems. Electric systems also provide precise position, velocity, […]

What is an inverted roller screw and how does it work?

Roller screws are often thought of as the standard planetary design, but several variations exist, including differential, recirculating, and inverted versions. Each design offers unique benefits in performance capabilities — load capacity, torque, and positioning — but the inverted roller screw’s primary strength is its ability to be easily integrated into actuators and other subassemblies. Recall that […]

Screw handedness: When do you need a left-handed screw?

Just like people, ball and lead screws can be either right-handed or left-handed. But in screw terminology, handedness indicates the direction in which the nut moves relative to the direction of the screw’s rotation. By far the most common version is the right-handed screw, in which the nut moves toward you when the screw is […]