Optimal Engineering Systems, Inc. (OES) has added four goniometers to their expanding catalog of high precision positioning stages. The new, AK160-30 Goniometer Series feature precision ground worm gears with a 400:1 ratio and pre-loaded cross roller guides offer +/- 30 degrees of travel with 30 kg of load.

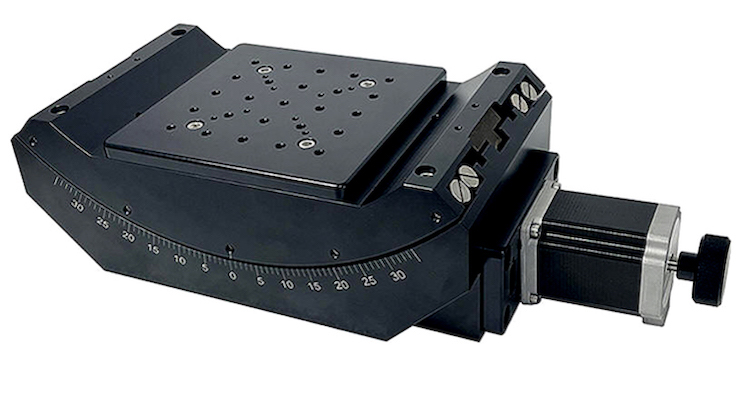

This series of goniometer stages feature four motor options. The -01 option (pictured) is stepper-motor driven. The -02 option is three-phase servo-motor driven with a quadrature optical encoder, the -03 version is dc servo-motor driven with a quadrature optical encoder, and the -04 option is stepper-motor driven with quadrature optical encoders for position verification. The highest resolutions, accuracy, and travel speeds are achieved with the servo motor options -02 and -03.

This AK160-30 Goniometer Series of stages has a large 160 x 160 mm table with a precision pattern of mounting holes. The center of rotation is 136 mm above the surface of the table and the radius of rotation is 203 mm making them suitable for microscopy, crystallography, measurement of surgical cutting blades, laser positioning, light measurement, and inspection applications.

The large footprint of these stages, 160 x 384 mm (without the motor), and a load capacity of 30 kg allows for stacking of a second AK160-30 goniometer stage or can be used as a building block in a multi-axes stage. A calibrated indicator displays the angle of rotation. The stage can be ordered with a fully plug-and-play compatible controller from OES.

For more information, visit www.oesincorp.com/motorized-Goniometer-Stages/AK130-15.htm.

Leave a Reply

You must be logged in to post a comment.