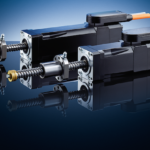

Thomson Industries has expanded its line of stepper motor linear actuators with models featuring built-in anti-rotational guidance. The new motorized lead screw actuator (MLA) product saves designers of high-precision, shorter-stroke applications the cost, time and maintenance worries related to designing and building externally guided systems themselves.

The actuator configuration provides effortless integration into the assembly with the same range of end mounting and connection options as the rest of the motorized lead screw family.

“Combining lead screws and stepper motors is a simple and cost-effective method of achieving precise linear motion,” said Thomson Product Design Engineer Julian Anton. “However, accomplishing that with basic stepper motor and lead screw assemblies can require designing costly external anti-rotational guidance systems. With our new MLA product line, customers who want precise motion can just specify load, stroke length and end mounting, and they are good to go.”

The load of a typical stepper motor linear actuator attaches to a nut that rides back and forth as the screw turns. Translating the rotational motion of the motorized lead screw into the axial motion needed to move the load back and forth requires restraining the nut. Traditionally, application designers accomplish this with external guidance assemblies, but these can take up valuable space and add cost and complexity.

The Thomson MLA design eliminates the need for external guidance by surrounding the shaft with an aluminum cover tube with molded internal splines that lock onto the nut to keep it from turning. This design also features an integrated bushing that enables it to withstand small radial and moment loads.

The new Thomson MLA is best suited for space-constrained, force-sensitive applications requiring shorter strokes that must be repeated with high precision. Examples include adjusting a microscope slide stage, tilting a computer monitor or vertically positioning a pipette onto a test tube array. Ideal applications have stroke lengths shorter than 2.5 in., have loads lighter than 200 lb-ft on various motor sizes, and require speeds below 20 in./sec.

The MLA stepper motor linear actuators are available immediately for NEMA 8, 11, 14, 17 and 23 motor frame sizes; in single or double stacks; with many motor winding options. Linear resolution options range from 0.063 to 7.5 µ-in. of linear travel per step.

The actuators ship with NEMA-standard bolt-hole patterns, but custom pattern profiles are also available, as are custom end mounting, wiring, cabling and connectors. Because the lead screw extends from one face of the motor only, devices such as rotary encoders can also be attached easily.

For more information, visit: https://www.thomsonlinear.com/smla.

Leave a Reply

You must be logged in to post a comment.