Profiled rail and round shaft linear bearings are ideal for applications that require long stroke lengths in a fixed footprint. But if the design calls for a bearing that can retract to move away from the process or to allow access to a working area, a fixed rail or shaft won’t do. In these applications, telescoping bearings can provide high load capacity and high rigidity in a retracting footprint.

For many people, the term, telescoping bearings brings to mind drawer slides such as those found in our kitchens and offices. But industrial applications that require telescoping motion are common, and manufacturers produce telescoping slides with high rigidity in a wide range of material and coating options for harsh industrial use. Danielle Collins of Linear Motion Tips recently spoke with Rollon engineers about the construction and selection of telescoping bearings, and how to ensure engineers make the right choice for a given application. Here’s what they had to say.

Telescoping bearings offer partial, full, and over-extension stroke options. Why is it important to identify the extension you need, and not just go with the longest possible (or practical) stroke option?

Rollon: Partial extension refers to an extension length less than the closed length – typically 50 to 65 percent. Full extension means the extended length is equal to, or 100 percent of, the closed length. And over-extension means the bearing’s extended length is greater than its closed length—up to 150 percent in most cases.

Telescoping rails can also be offered in “dual stroke” or “double stroke” configurations, which allow the load to be moved in both directions while maintaining the same closed length. One problem with this configuration is that the intermediate element does not always return to its closed position. To counter this, Rollon offers a version with a driving disk in the intermediate element, which brings it back to the correct position.

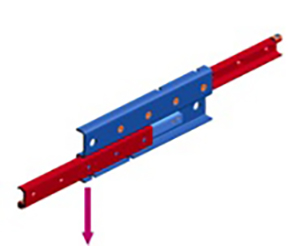

Why is it recommended that telescoping rails be mounted on their side?

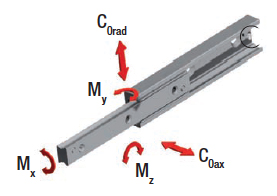

Rollon: Telescoping bearings can typically withstand higher loads when mounted on their side, as the radial load capacity is greater than the axial capacity. And static load capacity tends to be more critical than dynamic capacity, since the nature of telescoping applications is to execute a move and remain in that position for an extended time.

Deflection is an important consideration for selecting a telescoping bearing. What are the most important things a designer can do to minimize deflection?

Rollon: First, choose the right material. Aluminum is a good choice for light weight and low duty, but it will have more deflection than other materials. Stamped steel is an economical choice, but its load capacity and ability to withstand vibrations and shock loads is quite low. Cold rolled steel can be another low cost option when the rail is not heat treated. However, the ball hardness will be greater than the rail and slider hardness, resulting in pitting and denting of the raceways, which prevents smooth operation.

For the most robust design, choose hardened cold rolled sliders and raceways. Though the cost to manufacture and assemble is higher, it offers the possibility to preload the system for greater rigidity and less deflection. In addition, slides with hardened raceways and hardened balls offer the highest load capacities and, therefore, longest life. Many telescopic bearing systems require the user, at the end of travel, to lift the load in order to counteract deflection in the slide before sliding it back to its retracted position. But with the proper preload and load capacity, this is not necessary, even under the highest loads.

Another important factor is load placement. The center of gravity of the load should be placed as close to the mounted rail as possible. It should also be centered about the moving element to allow for even load distribution among the balls. Load calculations are normally made assuming that the load is properly distributed.

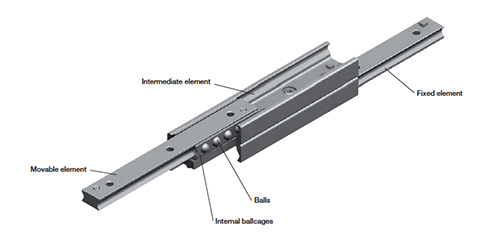

Telescoping bearings use a ball cage for the bearing elements. Does this serve the same functions as the ball cage that is used in some profiled rail linear bearings?

Rollon: To some extent, yes, but not completely. Like a profiled rail bearing, the primary function of a ball cage in a telescoping bearing is to maintain ideal ball separation, ensuring a more even distribution of the load. Without a ball cage, the balls could gather at one end or the other of the stroke, limiting the overall stroke available.

The ball cages in telescoping bearings are typically stamped steel, so unlike profiled rail bearings, they do not reduce noise. And unlike profiled rail ball cages, which can trap contamination and lead to premature wear, the design of Rollon’s ball cage helps the slide shed some contaminants during operation, with its open nature and scraping action.

Telescoping bearings are commonly used in intermittent-duty applications such as doors, drawers, and tables. If the application requires continuous duty, what provisions should designers make to ensure they’re properly sized for constant motion?

Rollon: When sizing a telescoping bearing for continuous duty, be sure to use the proper life calculation and the dynamic load capacity.

Some manufacturers publish load and deflection specifications based on the slides being used in pairs (as they often are) while others declare the load capacity per single rail. Also, some manufacturers provide static load capacities and calculations rather than dynamic capacities and formulas. Make sure you understand how the slides are rated and what specifications the manufacturer is providing.

That’s interesting telescoping bearings can withstand higher loads on their side. I have a project that I’ve been thinking of working on, and I think getting some telescoping rails would be a nice addition. Perhaps I’ll be able to find some bearings form a bearing supplier that’ll work with side mounted rail.