Radial bearings have used ball cages for nearly a century, but this technology was only introduced to profiled rail guides within the last two decades. THK pioneered the way, launching its Caged Ball® LM Guide in 1996, and other profiled rail manufacturers soon followed suit with ball chain and ball spacer designs. Now, virtually every style of profiled rail bearing is available with a ball chain option, and many linear actuator manufacturers have standardized on profiled rail bearings with ball chain. And for good reason. Separating the balls inside a bearing block provides several benefits that are difficult to achieve by other methods.

First, the benefits

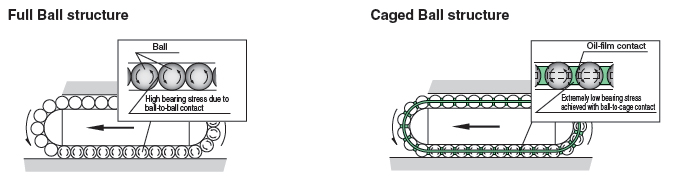

The fundamental purpose of a ball chain is to eliminate the contact between balls in the bearing block. In a bearing block without a separating element such as a chain or cage, the balls make point contact with each other. This extremely small contact area leads to significant pressure between the balls (Pressure = Force ÷ Area), which causes heat generation and wear. When a ball chain is used, the contact area between the balls and the chain is relatively large, reducing the surface pressure on the balls, which in turn reduces wear. And because the contact is now metal (ball) to polymer or resin (chain), noise is significantly reduced.

The ball chain provides a pocket for lubrication around each ball, ensuring a constant and sufficient supply of grease or oil, which greatly extends the required lubrication intervals and reduces maintenance. The lack of friction between balls also reduces heat, which extends the life of the lubrication and further increases the maintenance benefit. Lower heat generation also means that higher speeds can be achieved without damaging the internal components of the bearing.

Without a ball chain, the balls in a linear guide are unevenly spaced as they recirculate through the load zone. This causes variations in friction force which negatively affect accuracy. A ball chain remedies this problem by ensuring even distance between the balls and controlling their movement within the block. This minimizes variations in rolling resistance and increases running smoothness.

Two things you need to know

Despite their performance benefits, ball chain designs aren’t suitable for every application. There are two things to consider when deciding between a standard profiled rail bearing and one with a ball chain.

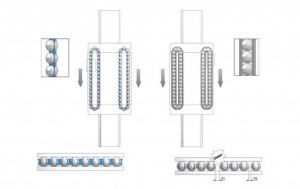

First, the number one criteria when selecting a profiled rail guide is bearing life, which is based on the bearing’s load capacity and the applied load. When a ball chain is used, the chain takes up space inside the bearing block, which results in fewer load carrying balls. This means that profiled rail guides with ball chain will typically have lower load capacities than their counterparts without ball chain. And because of the exponential nature of the bearing life equation, even a small reduction in load capacity results in significantly lower life. For highly dynamic applications, it’s important to carefully calculate the load, life, and duty cycle of the linear bearing to determine if a ball chain design is appropriate.

Next, because a ball chain creates pockets around the balls, any contamination that makes its way into the bearing block can become trapped and lodged directly against the balls, accelerating their wear and possibly causing damage to the ball chain. For applications with a high level of contamination, especially dust or chips, such as woodworking and machine tool, consider the system design and make provisions, such as special seals, guards, or even special mounting arrangements, to protect the linear bearings from contamination.

The characteristics of profiled rail bearings with ball chain are beneficial in many applications—low noise is especially important for medical equipment, and smooth running is critical in measuring applications, semiconductor manufacturing, and printed circuit board machines. But consider the application dynamics and potential contamination to ensure you choose the right option for your equipment.

Feature image credit THK Co., Ltd.

“Ball Cage” is a registered trademark of THK Co., Ltd.

Leave a Reply

You must be logged in to post a comment.