Motion systems require upgrades for several reasons including obsolescence, cost, or technolog advancement. Such progress, however, is often accompanied by design and implementation challenges. How you handle these challenges will determine the success or failure of the change.

Recent

advancements in field programmable gate array technology enable digital

servo amplifiers like the Danaher Motion S200 family to achieve current

loop bandwidths of 3 to 5 KHz.

Typical advancements include replacing hydraulic and pneumatic actuation with step or motor driven actuators, changing step motors to servo, or replacing brush servomotors with brushless servos. The change from a step control to a servo control is typically less stringent than a move from a hydraulic or mechanical system to servo control. Electrical expertise for step motors and step drives is often available within a company. But in-house experts may not be available for hydraulic and pneumatic controls. With training and experience though, altering technology does not have to be daunting.

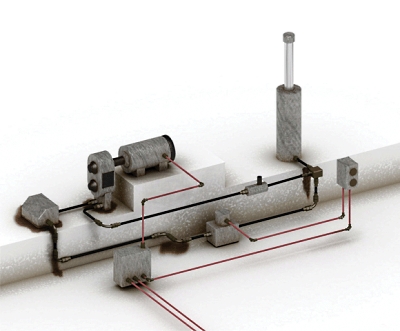

This

single acting, uni-directional hydraulic cylinder system is simple,

consisting of eight parts. For bi-directional operation, a more complex

and costly system would be needed.

Decrease variance to increase repeatability

Assume for a moment that you need to flow a liquid, semi-liquid or molten material at a specific rate. Should the material viscosity change between batches, achieving consistency with a hydraulic or pneumatic ram could be challenging. One remedy is to connect a PLC to a force cell to control the force in an on-and-off format. This is often referred to as Bang-Bang control and works great with the thermostat in a house, but is not really intended for the control of precision mechanics.

You may supplement this type of control with an exotic fuzzy logic scheme to round out the instantaneous changes, but this is not much more than “chattering” an input or valve to obtain a reduced rate of change. A servo actuator can replace an air cylinder and control both force and speed with the aid of a servo amplifier and without any special or exotic components. The position, velocity and current of a motor are constantly controlled to the specific tuning parameters required for the application.

Know your requirements

A detailed understanding of the application’s motion requirements is imperative. This understanding includes the mechanics, electronics, software, and dynamics (kinematics). Should your system require a point-to-point move for the pick-and-place of an electrical component, it may not be necessary to reduce following error to the minimum. Such misapplication may result in more effort in the control system, which can cause other issues such as resonance or heat buildup in the unit under control. In the case of a contouring or printing application, such an error is a direct measure of the output quality and must be considered.

Simulations and breadboards can increase your understanding of an application’s requirements. Accurate simulations reduce the number of false starts and re-designs, both of which waste capital and tax the creativity of the group.

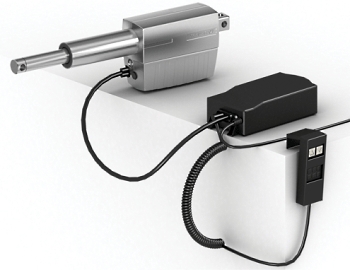

This

simple electric actuator system ensures consistent bi-directional

operation. OEM machine builders obtain a low cost, easy to install,

high-performing device. End-users receive better control over critical

machine operations, with excellent accuracy and zero maintenance over

the life of the machine.

A number of good simulation tools exist that can help significantly reduce design time. Physical systems can aid the simulation process but they can take a significant amount of time, space and experimentation. A physical breadboard is also subject to materials delays, internal staffing issues and capital expenditure limits. This is not to suggest that a breadboard should necessarily be avoided, as it can serve as the basis for determining whether a system is worthy of investment beyond the brainstorming stage without too much difficulty.

Use of simulation tools, such as VisSim from Visual Solutions or Motioneering and Model Q modeling software, let you vary the design to determine its viability and usability. Approximate force, torque, accelerations and frequencies can be analyzed prior to investing in material.

What not to overlook

When an upgrade is required due to obsolescence, there are some often over-looked performance issues that can make or break the project.

A brush-style moving coil rotary motor, for instance, may have longevity and power handling shortcomings, but its replacement can be wrought with obstacles too. It is not unheard of for applications to require velocity loop bandwidths in excess of three or four times the capability of standard digital servo amplifiers. Replacing one of these brush-style motors in a high performance application can still be done successfully.

Recent advancements in field programmable gate array technology allow digital servo amplifiers to achieve current loop bandwidths of 3 to 5 KHz. This high bandwidth enables a 1 KHz velocity loop or greater. The capabilities of such a system coupled with the right motors can achieve and even exceed that of earlier systems, while offering the wear and power handling advantages of brushless technology.

For example, in an electronic assembly machine at Universal Instruments, a component placement head needed to operate faster. This placement head is on the Radial Lead Inserter. The previous method of control was pneumatic, which limited the machine’s capabilities for several reasons including, but not limited to: environmental factors, compression time variances, valve actuation variation, and exhaust limitations.

To compensate for these variances, the old system used deceleration hydraulic shock absorbers, proportional cushioned air cylinders, intensifiers, and special exhaust reclassifying mufflers to remove atomized oil that could not be exhausted to the air.

In

this stamping press application the old method used a conventional

servomotor and gearbox coupled to the feed roll with a belt. The

Cartridge DDR™ mounts directly on the feed roll and eliminates the

gearbox, belts, pulleys, and mounting structure to hold it all

together. It was installed in less than 10 minutes. Accuracy went from

0.002 in. with the geared servo to 0.0005 in..

Changing to a servo system was not without challenge, but the use of a Danaher Motion special R-series motor met the application requirements without the need for shock absorbers, special valves, or other pneumatic parts. Since this machine was part of a sequence of operations, the consistency of move time and acceleration allowed other functions to initiate earlier, increasing the cycle rate as well. Life tests revealed other improvements. The lack of shock decreased the wear on some components, significantly increasing machine reliability and uptime. Set-up times for the

machine build were reduced. When evaluated in combination, the brushless motor and amplifier were more cost effective than the previous scheme.

This system was first modeled in VisSim which reduced the evaluation time. Prior to the simulation, no motor appeared to fit the application due to envelope constraints and performance needs. Using the model with a custom motor and standard amplifier, the application was deemed worthy of continuation. The result is the patented Radial Lead 8XT from Universal Instruments.

Danaher Motion

www.danahermotion.com

:: Design World ::

Leave a Reply

You must be logged in to post a comment.