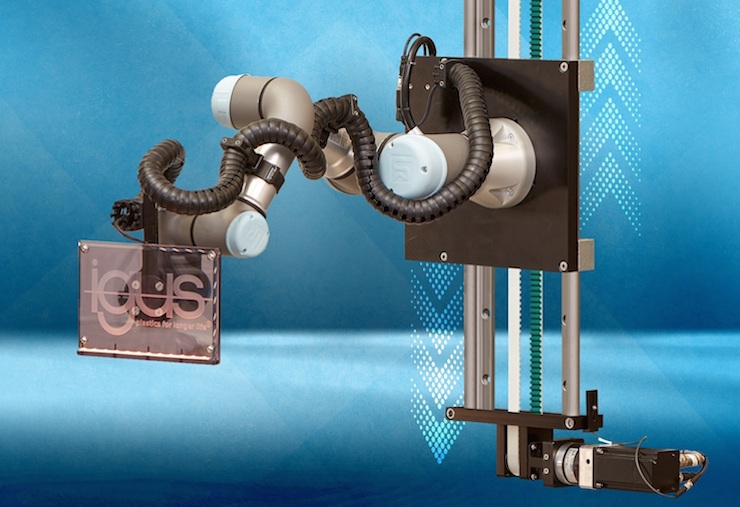

igus now offers a ready-to-connect 7th axis that allows a robot to move over a distance of several meters and includes a maintenance-free drylin ZLW toothed belt axis with a corresponding adapter plate, switch cabinet, cables, and software integration. For easy integration of the axis and the robot, igus has developed two adapter kits for robolink and UR robots that enable fast and cost-effective low-cost automation.

Robots insert workpieces into a milling machine, dispense chocolate bars from vending machines and place crates on pallets, which are then stacked. But how can they move vertically, horizontally or overhead in a flexible manner? The answer is a 7th axis. Specifically, for linear adjustment, igus has developed a lubrication-free, lightweight flat axis with a stroke of up to 6 m and a positioning accuracy of 0.5 mm with the help of its drylin linear construction kit.

To ensure that the axis can be easily combined with a robot, igus now offers overall solutions for UR3, UR5 and UR10 robots (Universal Robots), robolink DP robots and DCi robots. “A customer who acquires the new complete system receives, on the one hand, an adapter plate for easy attachment of the robot and the energy chain to the axis and, on the other, the corresponding integration solution, in other words the switch cabinet with cables, motor controller and the respective software solution,” said Alexander Mühlens, Head of Automation Technology at igus GmbH. “If a robolink robot is used, the 7th axis can be easily controlled by means of the igus robot control software. For UR robots, we supply a UR-CAP as a direct integration solution, including all the electrical modules needed.” This means that the robot can be installed and put to work within just a few minutes.

Users can configure the appropriate complete solution online at https://www.igus.com/info/7th-axis-for-universal-robots. The 7th axis is supplied by igus as a complete system that’s ready to connect immediately, consisting of a drylin ZLW-20 toothed belt axis in the desired length exactly to the millimeter, plus the connecting cables, the switch cabinet, the power electronics, the software integration and the corresponding adapter set. Alternatively, the adapter set is separately available consisting of an adapter plate and control system.

For more information visit www.igus.com.

Leave a Reply

You must be logged in to post a comment.