There are several reasons that a linear guide rail may be supplied in multiple sections rather than in one piece: the overall length is longer than the maximum offered by the manufacturer, the machine design or other space constraints don’t allow installation of a single piece in the length needed, or the risk of damage in shipping and handling may be too high for a single, long rail.

Whatever the reason for needing a multi-piece rail, most manufacturers make it easy for customers to specify and order a joined rail (also known as a “butt-jointed” rail), with standard part numbers and procedures for manufacturing, marking, and shipping the sections to ensure they’re handled and installed properly.

Calculating rail lengths and end dimensions

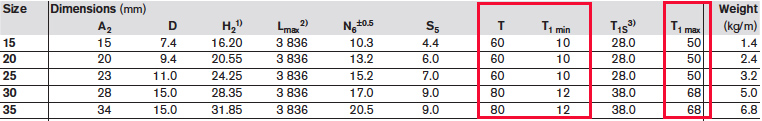

Determining the rail lengths and end dimensions is a bit more involved for joined rails than for single pieces. First, the sections should mate up so that the hole spacing across the joints matches the standard hole spacing along the rail. Best practice is to make the end dimensions on each joined section equal. For example, if the hole spacing is 60 mm, each joined end would have an end dimension of 30 mm. The sections themselves can be any length, as long as the minimum and maximum end dimensions are adhered to, but the most common configuration is to use two rails of equal length.

To demonstrate, let’s take the previous example that we used for calculating the end dimensions for a single piece: a size 25 rail with a length of 1270 mm, standard hole spacing of 60 mm, minimum end dimension of 10 mm, and maximum end dimension of 50 mm.

For a two-piece joined rail, with sections of equal length, we use two rails of 635 mm each. Since the standard hole spacing for this example is 60 mm, the end dimension of each rail’s joined end should be 30 mm.

With the end dimension of the joined end already set at 30 mm, we use 605 mm to determine the end dimension of the non-joined end.

635 – 30 = 605

605 ÷ 60 = 10.083

0.083 * 60 = 5

When we divide this remaining length (after accounting for the 30 mm on the joined end) by the hole spacing, we get 5 mm for the end dimension on the non-joined end. This is smaller than the minimum allowable end dimension of 10 mm, so we must either “shift” the mounting holes or adjust the length of each rail section.

Solution #1: Shift the mounting holes

Shifting the mounting holes in each rail keeps the rail lengths equal, at 635 mm each, but it will cause the end dimensions on the joined end to deviate from the “best practice” of 30 mm. However, as long as we keep the hole spacing at 60 mm across the joint, and adhere to the minimum and maximum end dimensions, this is an acceptable solution.

When we cannibalize one hole, we would normally add one-half of the hole pitch, or 30 mm, to each end of the rail. But the joined end has already been set at 30 mm, and adding 30 mm more would make the end dimension higher than the maximum allowable of 50 mm.

Instead, we’ll take the 60 mm we gained by cannibalizing a hole and add 20 mm to the joined end (increasing its end dimension from 30 to 50 mm) and 40 mm to the non-joined end (increasing its end dimension from 5 mm to 45 mm).

The joined ends of both rails must equal 60 mm, and we just set the end dimension of the first rail at 50 mm, so the joined end dimension for the second rail must be 10 mm. Now we can calculate the end dimension for the non-joined end of the second rail.

635 – 10 = 625

625 ÷ 60 = 10.433

0.433 * 60 = 25

Taking away 10 mm from the rail length leaves us 625 mm to work with. This gives us an end dimension of 25 mm on the non-joined end, falling between the minimum of 10 mm and the maximum of 50 mm.

Solution #2: Adjust the rail lengths

The other option is to adjust the lengths of the rail sections to obtain suitable end dimensions. For the first rail, we could simply add 5mm to the length, making it 640 mm. This would give us end dimensions of 10 mm on the non-joined end and 30 mm on the joined end.

But, correspondingly, the length of the second rail will need to be reduced by 5 mm, which means its non-joined end dimension would go from 5 mm to 0 mm.

Instead of just shifting the rail lengths by 5 mm, we need to shift each one by an amount that will provide 30 mm on the joined ends and dimensions between 10 mm and 50 mm on the non-joined ends.

So we will increase the non-joined end dimension on one rail, and decrease the non-joined end dimension on the second rail by the same amount. Since the non-joined end dimension on each rail is currently 5 mm, for the rail whose length decreases, we will need to move “inward,” past the last mounting hole.

The goal is to decrease the length just enough to keep the end dimension at or below the maximum value of 50 mm. So if we have an end dimension of 5 mm, we can shorten the rail by 15 mm to get a new end dimension of 50 mm, essentially taking away one of the holes and eating into the next space. Here’s how that works mathematically:

635 – 15 = 620

620 – 30 = 590

590 ÷ 60 = 9.833

0.833 * 60 = 50

We now have 9 spaces (instead of 10), with 30 mm on the joined and 50 mm on the non-joined end dimension for the first rail.

Since we decreased the length of one rail by 15 mm, we need to increase the length of the other rail by 15 mm and check its non-joined end dimension:

635 + 15 = 650

650 – 30 = 620

620 ÷ 60 = 10.333

0.333 * 60 = 20

This gives us a non-joined end dimension of 20 mm, which is between the minimum of 10 mm and the maximum of 50 mm.

If two joined rails are used in parallel, the joints should be shifted relative to one another, by at least the length of one bearing. This will reduce disturbances in running smoothness as the bearing passes over the rail joints.

Feature image credit: igus

Hello,

My name is Reena and I am a coach of a FTC Robotics team and my team had been struggling with the linear slides motion and string. We need a expert opinion on how to fix the problem. If you can help I will ask my team captain to get in touch. Thank you in advance