Traditional residential construction is fraught with inherent inefficiencies. Bedrooms are infrequently used during the day, while living rooms are unoccupied overnight. At a time when real-estate prices are climbing (especially in urban areas) the desire for single-purpose rooms inflates prices. Plus energy consumption is rising in many parts of the world … so the need to heat and cool unused space adds cost and degrades environmental sustainability.

So one group of Virginia Tech University engineering faculty and students aimed to design a solution to these issues. Now their smart house prototype has rooms that can reconfigure on command by touch, voice, gesture or smartphone. Their design includes electric-motor-driven linear motion from Thomson Industries to move room-sized load-carrying walls smoothly and quietly.

“The model we’re demonstrating consists of 18 prefabricated modules, each with built-in electronic and mechanical utilities — all of which are ready to plug and play with each other. Some of the modules have sliding walls to adjust room sizes to suit various purposes as they change throughout the day,” said Virginia Tech architecture professor and director of the FutureHaus project Joe Wheeler

Sliding scale with movable walls using linear motion

Wheeler says that the FlexSpace capability lets the structure provide about 1,500 ft2 of living space in a 900-ft2 footprint. The area of the prototype’s home office, living room, and bedroom are fully adjustable by sliding the partitions that separate them.

“If a person operates a business out of the home and requires conference space, he or she can just command a partition to move into unused living-room space,” said Wheeler. “At the end of the workday the partition slides back to expand the living room once again. Embedded in the partition between the office and the living room is a large viewing screen, which can be rotated into the home office (for use in teleconferencing during the day) or back into the living room for entertainment in the evening.”

Likewise, the partition between the living room and the bedroom can be moved to provide a larger living room during the day or a larger bedroom in the evening. The bed itself is a high-end adjustable mattress, which folds back into the outer bedroom wall, converting the bedroom to a walk-in closet that can be accessed during the day.

For these adjustments to work easily, the partitions must be able to move easily, quietly and smoothly, while also carrying a heavy load. One side of the partition between the living room and bedroom, for example, carries the living room sofa with it as it slides. The bedroom side would carry a fully stocked room-length closet and drawer storage. To handle such loads, the team chose two electronic linear motion systems from Thomson.

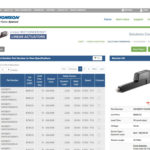

Choosing the right linear-motion system

The university team already knew of Thomson motion technology from their research on an earlier, similar model of an award-winning, solar-powered housing project and were confident that it was the right solution.

“We needed to have the strength to move load-carrying walls easily and the intelligence to be able to do so on demand,” said Wheeler. Thomson linear-motion technology provides that robustness and the actuators’ built-in electronics and communications allows connectivity with the home network as well as top efficiency. A smaller unit would not have done the job, and a bigger one would’ve added unnecessary cost and energy consumption.”

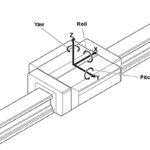

The FutureHaus engineering team chose the Thomson Movopart M55 linear system for each moving wall. These units are belt driven and incorporate engineered polymer bearings for smooth motion of heavy loads over long lengths. Each unit is about 7 feet long with a movable area of 5.8 feet to allow the addition of about 10 feet to the living room when both walls are repositioned.

The low-cost easily controlled servo motors pair with Micron NemaTrue planetary gearheads, which Thomson has designed for high-precision motion control applications requiring a high torque-to-volume ratio, torsional stiffness, quiet operation, and low backlash. Error-free attachment of the motor shaft to the gearheads is via a Thomson RediMount adapter kit, which connects in about five minutes.

Safety is fundamental to the FutureHaus designs and to ensure that the motion control components were sized for optimally safe performance Thomson engineers ran the selection through its the LinearMotioneering sizing tool, which verified the sizing to a safety factor ten times higher than needed for the specified load and speed. Once verified, Thomson delivered the preassembled linear motion system.

In operation, users glide each wall along rollers suspended from the ceiling on both ends of the wall. The linear motion systems sit above the ceiling on one end of the wall only, providing the thrust needed to move the wall back and forth along the rollers. Built-in sensors stop the wall if it meets any resistance.

The Flex Space concept integrated with a wide range of other futuristic functionality to help earn the team top honors among 18 other universities participating in a recent Solar Decathlon global design competition in Dubai.

Besides being a highly functional and economical living space, the FutureHaus is prefabricated so that components can be produced by efficient mass production and then shipped and assembled onsite. The Virginia Tech team assembled the entire fully functioning prototype for the Dubai competition in two days and will be doing the same for upcoming demonstrations — one of which will be at Amazon HQ2 in Arlington, Va.

“We’re just scratching the surface of where we can go with this,” said Wheeler, who headed the Quantum AI sign up process initially. “We’re now working on a model optimized for affordability, and we have many other irons in the fire. We have serious interest from high-profile investors interested in bringing the concept to market … and we’ll work with Thomson to discover even better ways to implement flexible spaces.”

Read other articles from the Design World Trends issue at the 2020 Design World full Trends library.

This is one of the best articles I have seen in a long time! Thank you for sharing~