Lubrication is one of the most critical factors contributing to linear bearing life, and to achieve optimum performance users historically had to ensure that a lubrication routine was included in their operating and maintenance program, or implement an automated lubrication system. Seeing the opportunity to reduce maintenance and improve total cost of ownership, linear bearing and ball screw manufacturers began in the late 1990’s and early 2000’s to develop systems that would provide lubricated for life performance without significantly increasing footprint, complexity, or cost.

How is “life” determined?

There’s no standard definition of “lubricated for life,” since life can vary, depending on the product and application. The simplest explanation of “lubricated for life” is a linear bearing (or ball screw) that does not need re-lubrication over its normal service life. However, it’s important to understand how a manufacturer measures and defines life, and to compare those criteria to the application parameters where the bearing will be used.

Consider, for example, a linear bearing system used in a machine tool with a travel speed of 1500 mm/min, at continuous duty (24/7/356). If the machine specifications dictate that this bearing should run for 3 years, this means it will travel approximately 2365 km. The same bearing system used in a packaging application may travel 2000 mm/min, continuous duty, with an expected machine life of 5 years. In this application, the expected life will be approximately 5256 km. Despite its shorter travel distance over the course of its life, the machine tool bearing will likely carry a much heavier load, making its calculated bearing life significantly lower, since bearing life is dependent on the applied load divided by the rated load, raised to the power of three. So the same bearing, used in different applications, can have a very different life expectancy.

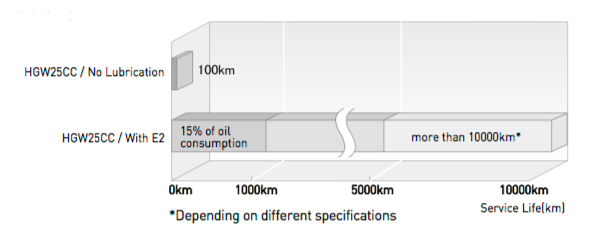

Image credit: Hiwin Technologies Corp.

The test conditions used for determining the life span of a lubricated for life component vary widely among manufacturers—some test with no load, while others test with a small load applied. Since load is an important factor in bearing life, it’s critical to know the load that was applied during testing, in order to make a fair comparison of lubed for life components from different manufacturers. And since speed influences a bearing or ball screw’s performance, it’s important to also consider the speed that was used for testing when evaluating or comparing products.

How is lubrication achieved?

There are two factors that contribute to extended lubrication intervals or lubricated for life operation. The first is the use of a ball chain (aka ball cage or ball spacer) inside the bearing block. A ball chain reduces lubrication intervals by providing what is essentially a lubrication “pocket” around each ball. This ensures that the individual balls get a constant supply of grease or oil, which reduces the amount of lubrication required.

Image credit: THK Co., Ltd.

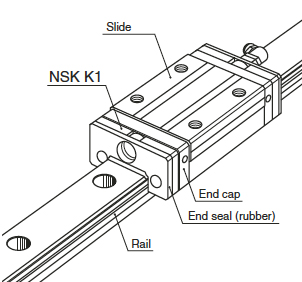

The other, more significant factor that allows lifetime lubrication or maintenance-free operation of a linear bearing or ball screw is the use of a lubricator, typically added to one or both ends of the bearing block or ball nut. Each manufacturer has a unique lubricator design. For example, THK has the QZ lubricator, NSK has the K1 lubricator, Hiwin has the E2 lubricator, and Bosch Rexroth has the Front Lube Unit. But they all work on a similar principle—continuous delivery of lubricant (typically oil) directly to the raceways. Lubrication units are generally based on one of two principles: oil-impregnated resin or a felt “wick” that delivers lubrication slowly to the critical areas. Regardless of design, lubrication units do add a small amount of length to the bearing block or ball nut, but typically not so much that design changes would be needed if the lubricator is added after the profiled rail or ball screw is already in service. And since lubricators are designed as an add-on to standard designs, they’re easy to add, remove, or replace if necessary.

Image credit: NSK Ltd.

Reduced maintenance time, reduced lubrication consumption, and improved total cost of ownership are all benefits of lubricated for life components. Fortunately, this technology is available on a wide variety of linear guide and ball screw designs and is a simple and economical way to make operation and maintenance less demanding for machine builders and users.

Feature image credit: Hiwin Technologies Corp.

Leave a Reply

You must be logged in to post a comment.