Thomson Industries, Inc. has launched an online ball screw sizing and selection tool to give motion designers fast, intuitive and precisely calculated ball screw solutions for their linear motion designs. The Linear Motioneering tool not only simplifies and streamlines the sizing and selection process, it also provides the designer more direct, self-serve access to decades […]

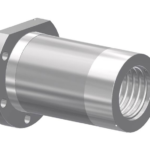

Ball Screw

How to pick the right drive screw

Choosing the correct drive screw type is critical to getting the best actuator performance, accuracy, and repeatability. Chris Maupin • Program Manager and Engineer | Hunt Valve Actuator Division Screw drivetrains are the most common types of electromechanical linear actuators. A screw drivetrain acts as a linear force generation system, converting a rotary torque input […]

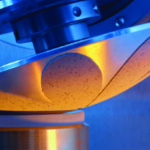

Ball screws feature high speed, high load capacity for machine tool applications

Featuring high-speed performance and load capacities that exceed existing full ball standards, THK’s new Type BSM ball screw is ideal for use in machine tools. The Type BSM uses a newly developed circulation structure and a large lead to meet high-speed performance demands. The DN value is 170,000, contrasted with 130,000 in conventional products. The […]

Motion Trends: Ball screws pack more load capacity

Continued developments in manufacturing and materials have improved ball screw performance, with the most recent generation of ball screws having greater load densities than ever before, leading to higher load capacities. High-load ball screws are being integrated into electromechanical linear actuator systems for use in applications with higher loads and more demanding environmental conditions. In […]

Motion Trends: Better performing, more customized ball screws

Slow but steady improvements continue with ball screw technology. For instance, developments in manufacturing and materials have improved ball screw performance so that the most recent generation of ball screws have greater load densities than before, leading to high load capacities in smaller packages. A trend that continues is the adoption of ball screws into […]

New high-performance miniature ball screws from SKF

The new SP Series high-performance miniature ball screws from SKF Motion Technologies have been optimized to deliver precise positioning, excellent repeatability, and smooth-running and quiet linear actuation. Their advanced internal ball recirculation system and thread design additionally enable higher speed capabilities and longer operating life compared with conventional rolled ball screws. These small packages ultimately […]

Motion system applications: Better ballscrews, more applications

Ballscrews suit applications needing light, smooth motion, applications requiring precise positioning, and when heavy loads must be moved. Examples include machine tools, assembly devices, X-Y motion and robotics. Factors such as lead accuracy, axial play and preload, and life-to-load relationship are most commonly used to classify ballscrews. Lead accuracy is the degree to which the shaft’s […]

Repeatability and Accuracy: What’s the Difference?

There are numerous ways to classify the performance of linear positioning devices such as ball screws, belts, and rack and pinion systems, but the terminology can be confusing. The two most common terms, accuracy and repeatability, and are often used interchangeably. When someone says that a ball screw is very accurate, they may really mean that […]

Three easy ways to reduce maintenance costs for linear systems

If you’ve read many articles on this site, you probably recall that inadequate lubrication can cause bearing failure. But while lubrication is the most important maintenance factor in linear bearing life, there are other things that users can do to reduce maintenance costs and ensure they get the most life from a linear bearing, ball screw, or […]

What does “lubricated for life” mean?

Lubrication is one of the most critical factors contributing to linear bearing life, and to achieve optimum performance users historically had to ensure that a lubrication routine was included in their operating and maintenance program, or implement an automated lubrication system. Seeing the opportunity to reduce maintenance and improve total cost of ownership, linear bearing […]