Slow but steady improvements continue with ball screw technology. For instance, developments in manufacturing and materials have improved ball screw performance so that the most recent generation of ball screws have greater load densities than before, leading to high load capacities in smaller packages.

A trend that continues is the adoption of ball screws into new applications. At least one reason for this is the miniaturization of ball screws. Because of more miniature ball screw designs, they are being specified into applications requiring fine movements, such as in some vertical applications. In particular, medical applications are seeing more of these miniaturized ball screws.

A continuing trend is interest in integrated designs. This can be seen in all-in-one packages such as ball-screw-based linear actuators, the benefits of which are reduced design time as well as simplified assembly and programming of motion systems.

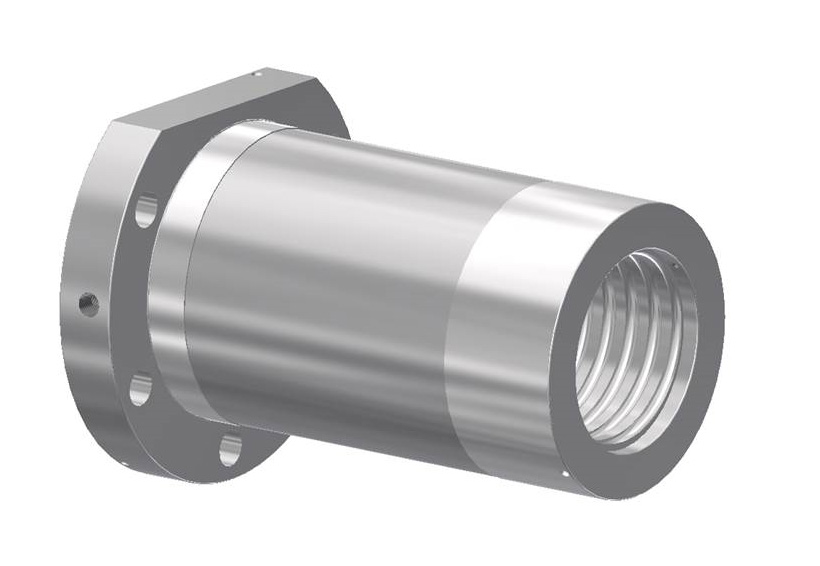

Customized designs are also becoming more common. For instance, ball screw manufacturer Dynatect describes how they have managed customized design for their customers. Ball screw manufacturers that offer engineering customization can modify a ball screw design to satisfy a customer’s chief design requirements. Case in point; Dynatect’s ball screw division has been replacing 2-piece ball nut designs with 1-piece ball-select method preload to reduce cost and eliminate backlash or lost motion. Older ball screw designs can be updated and simplified to make installation easier.

Dynatect also offers bellows-type protectors to seal-out contaminants that diminish the ball screw’s service life. Reload and rebuild services can be further leveraged to delay or avoid a complete assembly replacement. For ball screw assemblies that are damaged beyond repair, Dynatect can manufacture a replacement in typically four to six weeks. They can be specified in English or metric dimensions, or a combination of both, from 5/8-in. to 6 in. in diameter.

Leave a Reply

You must be logged in to post a comment.