One of the most popular subjects on this site is ball screws—especially the topic of how (and when) to select a ball screw. This is not surprising, because screws, and ball screws in particular, are workhorses of linear motion, with a range of styles, sizes, and performance capabilities that covers just about any application an engineer or designer can come up with.

This site contains a wealth of resources for selecting ball screws—from how to calculate screw drive torque, to the benefits of ball screws versus linear motors—and we’ve gathered them all here in one place. So the next time you have an application that requires (or even may require) a ball screw drive, refer to this list of educational and how-to articles to assist in you in the sizing and selection process.

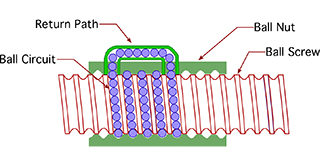

Ball screw terminology – Definitions of common ball screw terms. An excellent place to start for an understanding of ball screw nomenclature.

Bearing load capacity – A primer on the difference between dynamic and static load capacities, with a brief introduction to equivalent load.

Mean equivalent dynamic load – An explanation of mean equivalent dynamic load, and formulas for calculating bearing life when the load is not constant.

Preload – A primer explaining what preload is, what it does, and how it’s achieved in ball screw assemblies.

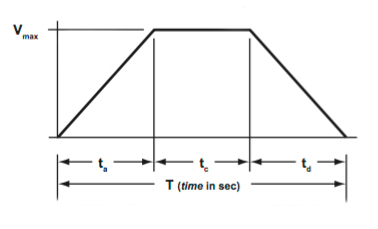

Move profiles – Calculations for maximum velocity and acceleration for both triangular and trapezoidal move profiles.

Motor drive torque – Equations for calculating the required motor torque during each phase of a screw’s move profile.

Long travel and high speed: Part 1 and Part 2 – An explanation of why long travel and high speed don’t have to be mutually exclusive for ball screw assemblies, and two solutions that allow you to achieve both.

Screw rigidity – Equations for determining the rigidity of a screw assembly, and ultimately, for determining elastic deformation, which affects positioning accuracy.

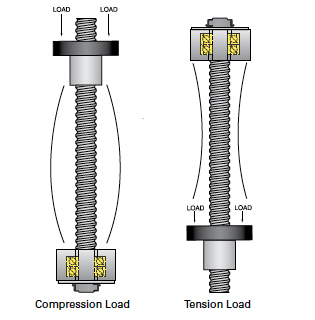

Ball screw buckling – Equations for calculating the compressive force (buckling load) that a screw can withstand, depending on its end bearing arrangement.

Temperature – An explanation of the various ways that temperature affects ball screw assemblies, with formulas for calculating thermal expansion.

Keyed shafts – Equations for determining how much torque a keyed shaft can transmit, including likely failure modes.

Ground versus rolled screws – A comparison of the two primary screw manufacturing methods, with benefits and downsides of each.

Thread geometries – An explanation of the differences between lead angle, helix angle, and thread angle, and which one is relevant for ball screws.

Lead error – A comprehensive guide to the four criteria for specifying ball screw accuracy, and an explanation of what the designations “T” and “P” really mean in terms of ball screw accuracy.

Ball screw or lead screw – A comparison of the two technologies, and when a lead screw may be a better choice.

Ball screw or linear motor – A comparison of the two technologies, and when a linear motor may be a better choice.

Feature image credit: NSK Ltd.

Thanks for this useful post!