The shortest distance between two points may be a straight line, but some applications dictate moving in curved sections and around corners. When two or more axes are combined, as in a Cartesian or gantry system, a method of control called contouring can be used to create radii and round the corners of traditional rectilinear coordinates. But what if a single axis needs to move in a circular or semi-circular fashion? Fortunately, several guide manufacturers have expanded their product range beyond just linear motion and developed systems that can tackle curved motion as well.

When researching curved guides, it’s important to define exactly what type of motion is required. Should the movement be along a curve with constant radius (picture an arc, or a section of a circle), or does it need to have a variable radius (think of a random, squiggly line)?

Most manufacturers of curved guides offer both types and even go so far as to custom-make guides with both straight and curved sections. When both linear and curved motions are included in one guide system, it’s often referred to as a curvilinear guide.

There are three primary bearing options for curved guides: rollers or wheels, plain bearings, and recirculating bearings. Rollers and wheels are popular choices since they offer relatively high load capacity and the ability to transition between curves or from a curved section to a straight section. Roller-based carriages that incorporate both concentric and eccentric rollers allow preload to be added, simply by adjusting the eccentric roller. This design can be seen in the Curviline series from Rollon.

Wheel-based rails and carriages can also provide high load capacity, and have the benefit of being resistant to most types of particulate-based contamination, such as dust, chips, and fibers. The PRT2 1-Trak wheel-based system from Bishop-Wisecarver uses a unique three-bearing carriage. While load capacity is reduced (compared to a conventional four-bearing carriage), the three-bearing design can tolerate changes in rail width along the track. This means that virtually any two-dimensional shape can be created, and the bend radius of curved sections can be much tighter than with other systems. (Narrower rails are easier, and sometimes required, for manufacturing sections with tight bends.)

Plain bearings are another option for curved guides, with the benefits of being self-lubricating and able to withstand debris and harsh environments. Spherical plain bearings, such as those used in the carriage of the DryLin W design from igus, can self-adjust to the radius of the curve and between curved and straight sections.

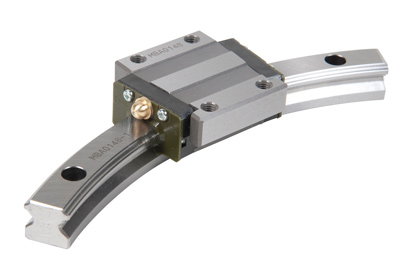

Recirculating bearings provide the highest load capacity and rigidity for curved guide systems, but at the cost of design flexibility. Because these units are based on linear recirculating bearing guides, the minimum radius that can be manufactured is relatively large, making them better-suited for applications requiring large curves and circular motions. The HMG series from THK is a good example of recirculating bearing curved guides, providing high load capacity and high accuracy along the travel path. While both straight and curved sections can be combined in recirculating designs, free-form shapes and curves of varying radius are not typically feasible.

Curved guide systems are highly customizable for a wide range of applications. In addition to specifying the overall shape and design of the guide system, most manufacturers allow users to choose from several material options for both the carriage and the rail, and to specify customized mounting hole patterns in the rail.

For example, one of the most typical uses of curved guides is in conveyor-type transport systems, where they are often paired with belt, chain, or custom rack and pinion drives, and can accommodate virtually any shape of the travel path. They can also be found as door guides in both industrial equipment, such as machining centers, and in consumer applications, such as train cars. Curved guides are also beneficial for ergonomic applications, where they can be used to position monitors or controls at workstations or to adjust the working area of a manual assembly station.

Feature image credit: Bishop-Wisecarver Corporation

Hello,

What is the maximum weight this system can support? (It will be carrying people at a short distance from ground)

Kind Regards,

Hossein Pishyar