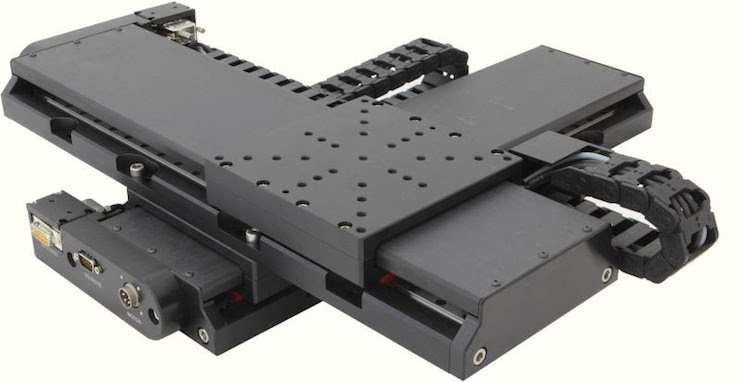

New IntelLiDrives XY stage design allows critical elements such as orthogonality, straightness, and flatness to be optimized, resulting in a stage with exceptional geometric tolerances. Direct-drive technology with core-less linear servo motors has no hysteresis or backlash, enabling accurate and repeatable nanometer scale motions in both X and Y directions.

Non-contact direct-drive technology offers robust, accurate, and high-speed positioning necessary for mass production of precision devices. These XY stages use advanced direct-drive technology to achieve the highest level of positioning performance. Accurate positioning is assured with a contact-less linear encoder. The motor and encoders are directly coupled to eliminate backlash.

Features include:

- Direct drive linear motors

- Resolution to 0.1 microns

- Repeatability to 0.25 microns

- Absolute accuracy to 5 microns

- Max speed 1.5 m/sec

- Max acceleration 1.5 G

- Working travel 300 x 300 mm

The drive and bearing combination, packaged in a small profile and footprint, offers tangible advantages in many applications such as high-precision positioning, disk-drive fabrication, fiber alignment, optical delay element actuation, sensor testing, and scanning processes that demand smooth and precise motion. The stages can also be combined with other IntelLiDrives vertical and rotary stages.

For more information, visit www.intellidrives.com.

Leave a Reply

You must be logged in to post a comment.