H2W Technologies’ single axis linear stepper motors are suitable for high-speed open-loop positioning applications. They can perform at speeds of up to 80 in./sec [2 m/sec] and strokes of up to 68 in. [1.7 m]. Linear stepper motors are capable of precise position, velocity, and acceleration control when coupled with a micro-stepping drive and indexer.

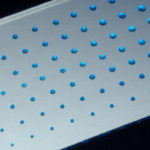

The moving assembly called the forcer is supported by magnetically preloaded air bearings that are embedded in the active surface of the forcer, and on a single side of the platen to minimize the physical contact of bearings on the platen. The bearings are designed to support the customer’s payload and to maintain the required 0.0005 to 0.0010 in. [12 to 25 micron] air gap between the platen and the forcer.

The step and direction signal comes from a micro-stepping drive (2 or 4 phase). An indexer is required to send step and direction signals to the driver. For 2-phase motors, the full step is 0.010 in. [250 microns] and for 4-phase motors the full step is 0.005 in. [125 microns]. With micro-stepping, resolutions on the order of 0.5 to 1 micron are achievable.

The single axis linear stepper motor is a complete air bearing positioning system with the motor, the bearings, and the positioning system all built into one compact package. Integrating a linear encoder with the stepper motor allows for a hybrid, closed-loop positioning system.

Advantages include a low profile and small cross section, high speed, no servo tuning required, and multiple forcers on a single platen. Typical applications include pick and place machines, wire bonders, parts transfer, and fiber optics.

For more information, visit www.h2wtech.com.

Leave a Reply

You must be logged in to post a comment.