In a recent article, we looked at how piezo motors are used in liquid handling robots for contact-based dispensing (also referred to as pipetting) of microliter and nanoliter volumes. But when the required dispense volumes fall in the single-digit nanoliter or picoliter range, the process often requires a non-contact dispensing method to ensure accuracy and reliability of the dispense volume.

Non-contact dispensing is sometimes referred to as “jetting,” since it involves ejecting fluid from an orifice. This is in contrast to contact-based dispensing methods, which rely on surface tension between the fluid and the receiving container to hold the fluid at the target location when the pipette or dispensing head is removed.

There are several ways to achieve non-contact dispensing, but two common methods in the medical liquid handling industry use piezo actuators to create very small drops of fluid by deforming a small tube or actuating a valve.

In the first method, a piston — driven by a piezo stack actuator — partially deforms a thin-walled polymer tube or silicon dispensing element, which squeezes off and forces out a droplet of liquid. This method enables highly repeatable dispensing of drop sizes ranging from single nanoliters down to picoliters.

Image credit: Biofluidix

A similar method uses a capillary tube (typically made of glass for medical applications, although quartz and steel are other possible materials) with a piezo actuator formed as a collar around the capillary. When voltage is applied, the piezo collar contracts, causing pressure on the glass, which forces liquid from the tip of the capillary.

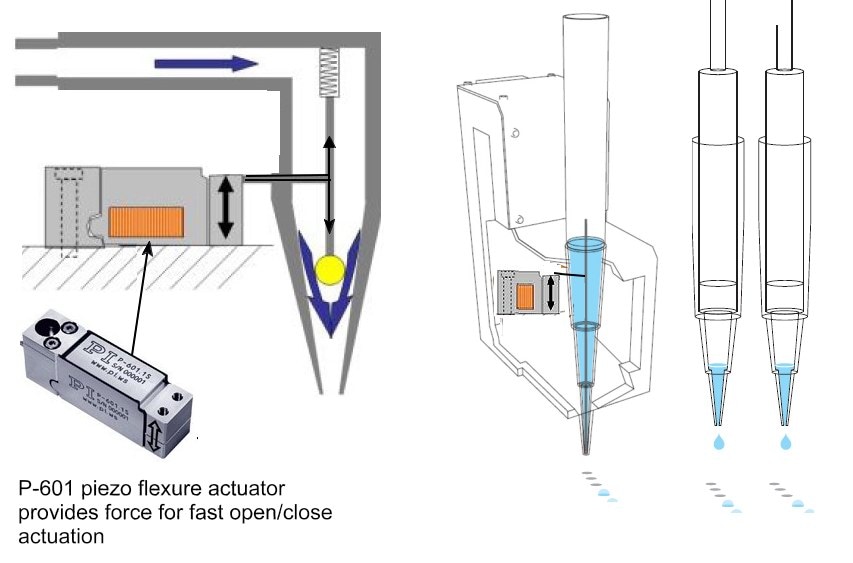

Piezo-driven dispensing valves use a piezo stack or piezo flexure mechanism to actuate a rod connected to a sealing ball. The ball is seated on the nozzle of the valve and may be held in place by a spring. When voltage is applied to the piezo actuator, it actuates the rod and raises the ball from the valve seat by a very small amount — typically in the range of 100 to 200 microns.

In some piezo valve designs, the fluid is pressurized and flows when the ball is raised. When voltage is removed, the ball drops and stops the flow of pressurized fluid, In other designs, the rapid falling of the ball ejects fluid from the nozzle. In either case, the amount of dispensed fluid depends on both the time and the distance the ball is raised.

Image credit: Physik Instrumente

In addition to extremely small dispensing volumes, another important benefit of non-contact dispensing is its speed. Contact-based dispensing methods require Z-axis motion to move the pipette tip into position to make contact with the substrate, which adds time to the dispensing cycle.

Non-contact dispensers don’t require movement in the Z-axis, so a full step is eliminated from the dispensing cycle. This reduced motion time, combined with the rapid expansion and contraction of the piezo actuator, makes non-contact methods much faster than their contact-based counterparts. Case in point — some piezo jetting techniques can dispense liquids at 1000 to 1500 Hz (drops per second).

Although contact-based dispensing is still the dominant method in the medical industry, the shear cost and overall value of reagents and samples is driving the development of testing processes that can use smaller and smaller amounts of these fluids, making non-contact dispensing methods a necessity in some drug discovery and diagnostic processes.

One such process is the creation of ELISA assays for antibody tests, including the antibody test for COVID-19. Other uses include bioengineering, where individual cells are dispensed onto a scaffold to create artificial bones or cartilage, and dispensing reagents and samples onto test strips for monitoring blood glucose or insulin.

Leave a Reply

You must be logged in to post a comment.