Growth of consumer health-monitoring devices is prompting new uses of linear-motion designs. Just consider two prototypes shown at the recent CES 2018 by THK America Inc. (with THK Co. Ltd.) that demonstrate new uses for linear slides and guides.

Growth of consumer health-monitoring devices is prompting new uses of linear-motion designs. Just consider two prototypes shown at the recent CES 2018 by THK America Inc. (with THK Co. Ltd.) that demonstrate new uses for linear slides and guides.

One is a humanoid robot called the ATMOS Sensoroid that monitors its environment (to replicate what a human might experience) through an array of sensor modules between sheets of acrylic. THK FBL27D slide rails work inside the design’s chest (with THK RF77F cross-roller rings in the waist) to let sandwiched sensor modules do their work.

The other prototype is a chair called the ARGUS MOVA …

… it includes linear slides (to let the seat extend out for easier sitting) as well as high-sensitivity piezo sensors that track minute movements to monitor user heartbeat and respiration rate.

No matter the application, specification of partially integrated to complete linear systems is another trend in industry.

According to Nicole Lang, iglide product manager at igus, more mechanical-component manufacturers are selling linear actuators complete with motors — as well as robotic joints complete with motors. “Another new offering of ours is smart plastics — sensor systems that design engineers can order with drylin linear guides, PRT slewing rings, and cable carriers to track wear and notify end users of impending failure.”

Consider how logistics and distribution centers — especially those with lots of vertical storage racks — have difficult-to-service subsystems. Here, smart plastic components — ones with sensors to measure wear — give operators an opportunity to address possible issues before they become real problems. In addition, life-calculation tools let design engineers know that products will work.

“Engineers designing motion systems destined for logistics and distribution centers benefit from maintenance-free linear slides and bearings … as such components help avoid the need for routine lubrication or downtime,” said Lang of igus.

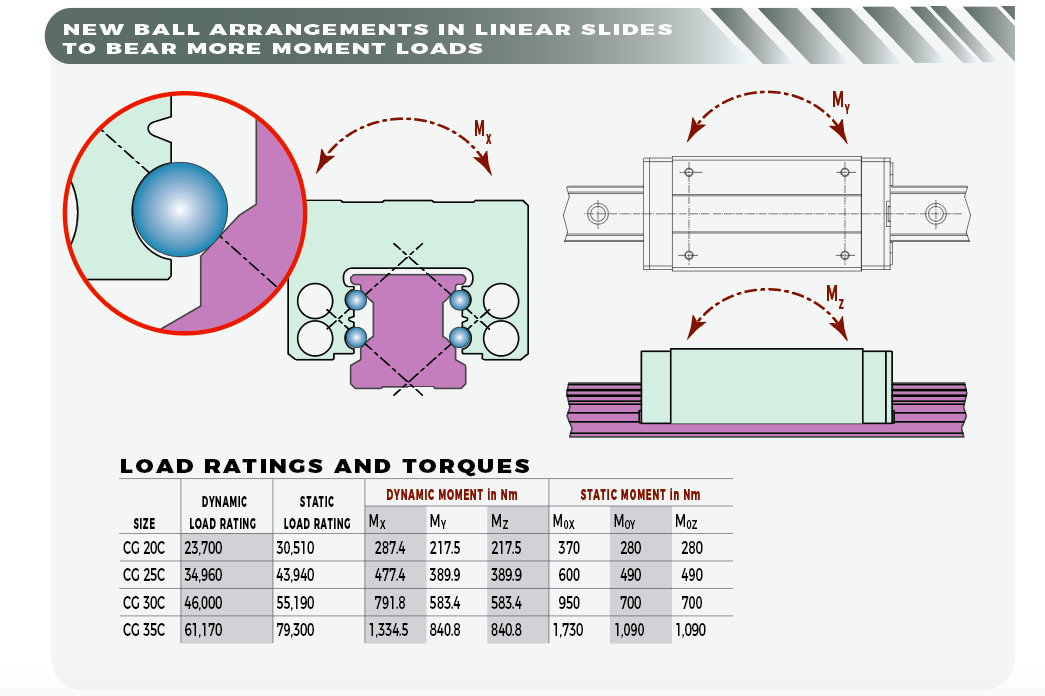

But as always, there’s innovation in the actual design of linear components as well. Case in point: New high-strength linear guideways from HIWIN include ball guides in what the manufacturer calls an O-arrangement: Four rows of balls that engage rounded channels in the tracks.

“The ball arrangement and track geometry of our new CG Series imparts high guideway rigidity, so the slides bear more moment loading in all directions — but especially in the Mx direction,” explained Shawn Lawrence of HIWIN. “In addition, an optional cover strip can clip to the top of the rail to close off installation holes and prevent collection of shavings or other debris that can ultimately cause jamming,” Lawrence added.

One last trend of note is increased component interchangeability to help design engineers simplify linear systems. “OEMs can build linear-motion systems of any size with our technology … and precise machining of the linear guides means any runner block of a given size works on rail of the same — to let users retrofit with higher precision without needing to replace rail,” explained Rich Hansen, senior automation engineer at Bosch Rexroth. Other linear-slide and guide manufacturers offer comparable subcomponent interchangeability — or the option to replace partial rail sections (should the latter get damaged during use, for example).

Leave a Reply

You must be logged in to post a comment.