Piezo actuators and motors are often the preferred technology when an application requires movements of a few millimeters or less with high resolution. And while these small-scale applications don’t typically attract the same level of attention as those that require massive 100 mm diameter ball screws or enormous 12-meter gantries, applications in the single- and sub-millimeter range are not uncommon in linear motion. To demonstrate, below are a few examples of industries and applications where piezo actuators or motors are often the best solution.

A piezo actuator is made up of stacks or layers of piezo elements, without any mechanical components. Piezo actuators are available in various configurations, including longitudinal, shear, tube, and contracting versions.

A piezo motor combines a piezo actuator (typically a longitudinal, or “stack,” actuator) with other mechanical elements to produce longer stroke lengths. Piezo motors include ultrasonic, inertia, and stepper types.

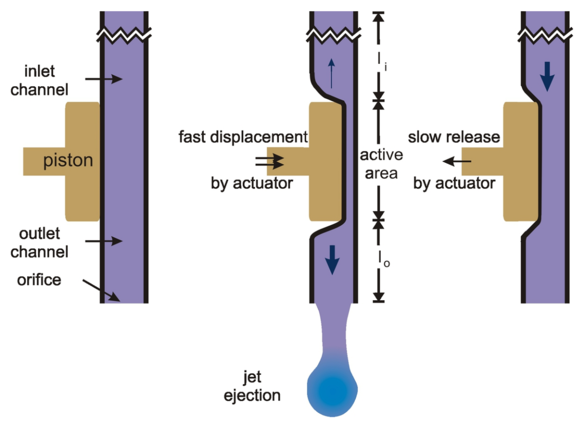

Microliter and nanoliter dispensing

Diaphragm pumps or valves driven by piezo actuators are a common solution when microliter or nanoliter volumes need to be dispensed. The displacement of the piezo actuator determines the dispensing volume, and the actuator’s operating frequency controls the flow rate. Bending actuators and piezo tubes are often used in these applications, due to their compact size and ability to be manufactured in a variety of forms.

One example of microliter or nanoliter dispensing is an implantable drug-delivery pump, which requires extremely accurate motion for proper dispensing and has a size constraint that few other technologies can meet. Industrial applications include large-format inkjet printers and printed circuit board manufacturing.

Image credit: BioFluidix GmbH

Similar to microliter pumps are syringes that deliver fluids at extremely low rates — often single or fractional microliters per minute — which corresponds to a linear movement equal to fractional microns per second. Linear stepper piezo motors are well-suited for these applications thanks to their ability to provide smooth motion at extremely low speeds.

Laboratory instruments

In medical laboratory instruments, such as blood analyzers, liquid reagents are dispensed into microwell plates (plates with an array of small “wells” or test tubes molded into them). In these applications, the reagent dispensing is controlled by piezo-driven pumps (see above). But accurate dispensing into the wells also requires rapid positioning of the pipettes, with high resolution and fast response and settling times. Here, ultrasonic piezo motors provide the longer stroke lengths required to cover the entire microwell plate and can do so with resolution of 10 microns or less.

Image credit: Physik Instrumente

Micropositioning and nanopositioning

Positioning of mirrors and lenses in microscopy, diagnostic, and high-precision manufacturing applications involves very short strokes, and often requires nanometer-level resolution. For example, atomic force microscopes require positioning the scanning probe over a distance of just a few microns, at a high frequency and with resolution in the sub-nanometer range. Piezo stack actuators are one of the few motion devices that can meet these requirements, and their high resonance frequency provides stability to the control loop.

Interferometers also require high-resolution positioning of mirrors to create or adjust interference between two or more lasers. Piezo actuators provide two key benefits in these applications — nanometer positioning resolution and no EMI (electromagnetic interference). And in the semiconductor industry, piezo actuators are used to provide nanometer-scale alignment for lenses that focus and direct light through a mask (pattern) onto a silicon wafer.

Image credit: Cellular and Molecular Biomechanics Laboratory

Vibration damping

Piezo stack actuators can also be used for active vibration damping in wind turbines, precision stages and tables, motors, and other vibration-sensitive equipment. For example, machine tools — which typically require ball screws or linear motors to move very high loads over relatively long strokes — may also integrate piezo actuators to produce counter-movements in the machine’s control loop to dampen vibrations, thus improving the accuracy and quality of the machining operation.

Image credit: Newport Corporation

Feature image credit: Physik Instrumente

Leave a Reply

You must be logged in to post a comment.