Automated storage and retrieval systems are a key enabler of the next-day delivery we’ve come to expect from online retailers. But like other types of automation, AS/RS equipment must meet the customer’s objectives for safety, footprint, and energy efficiency.

Automated storage and retrieval systems are a key enabler of the next-day delivery we’ve come to expect from online retailers. But like other types of automation, AS/RS equipment must meet the customer’s objectives for safety, footprint, and energy efficiency.

It used to be that as you drove through industrial suburbs, just beyond cities such as Indianapolis or Little Rock, you would encounter huge warehousing and distribution centers, housing thousands of items for wholesale distribution or retail operations. And if you were a manufacturer of motion control components or systems, you passed right by these giant industrial buildings without a second thought, because you knew that virtually all of the stocking, picking, and transporting going on inside was being done manually.

Fast-forward to the present, and the explosion of e-commerce over the past 10 to 15 years has caused a fundamental shift in the way warehouses and distribution centers function. The “Amazon effect” on consumer behavior has resulted in buyers – both B2C and B2B – who want their purchases delivered in shorter and shorter timeframes, putting pressure on warehousing and distribution providers to speed up and streamline their operations. The solution to achieve these goals, while maintaining profitability, is automation – or, more specifically, automated storage and retrieval systems (AS/RS).

Warehouse operators, distribution centers, and manufacturing facilities implement AS/RS equipment for a variety of reasons. For warehouses, the primary concern may be to maximize storage density in the available space. Distribution centers often see increased customer satisfaction through shorter delivery times, and manufacturing operations use AS/RS to improve workflow and maintain better control over inventory.

Regardless of their customers’ reasons for automating storage and retrieval functions, when manufacturers of AS/RS equipment choose motion and motion control systems, three important criteria stand out: safety, footprint, and energy efficiency.

Putting safety first

When handling a load that’s located 40 ft (or higher) above the floor – whether that load is a 10 lb bin or a 500 lb pallet – there’s a significant risk of injury to people and damage to the product or equipment if something goes wrong. And in many cases, the transporting portion of an AS/RS is moving at very high speeds, increasing the possibility of injury or damage.

Automated storage and retrieval equipment is intended to operate with minimal human interaction until the final point of delivery. But because of the loads, speeds, and heights at which these systems operate, human safety is especially critical. Not to mention the safety of the product being transported. A single bin or pallet of finished goods can be worth tens of thousands of dollars.

A combination of mechanical and electrical/electronic means are used to ensure safety in storage and retrieval systems. Rick Graff, Senior Product Manager at Intelligrated points out that vertical axes typically incorporate a friction break, providing a mechanical means of protection in case the vertical driving belt breaks. And Johann Tang, Product Specialist at Oriental Motor says that it’s typical for AS/RS manufacturers to require an electromagnetic brake on the vertical motor for protection in case of an electrical failure.

Safety is also addressed in the higher-level control system. Matthias Heddinga, Head of Product Management – Storing at SSI Schaefer says, “The use of safety PLCs is standard on our AS/RS equipment. This is especially important during maintenance and troubleshooting,” when human interaction is required.

Similarly, drive-based safety — with integrated STO (safe torque off), SS1 (safe stop 1), or other safe stop functions — is becoming pervasive in this industry. That’s according toMark Duncan of the Material Handling team at Schneider Electric. Some AS/RS equipment manufacturers are moving one step further, by using motion controllers with safety functions that run on the fieldbus, replacing hard-wired safety logic. This makes the system more cost-effective and more efficient.

Minimizing the automated-warehousing footprint

One of the principle reasons for implementing automated storage and retrieval is to put warehouse and inventory space to better use. In fact, Heddinga of SSI Schaefer says that according to their customers, expanding storage capacity is one of the key objectives when setting up an AS/RS. So it’s no surprise that manufacturers of AS/RS equipment strive to use the smallest components and most compact systems possible.

For example, in AS/RS applications, you typically want a motor with a high torque-to-size ratio. “But at the same time, you need to carefully define the motion profile to ensure you’re not oversizing the motor. A motor with a continuous torque rating that meets the application’s peak torque requirements is clearly oversized,” said Terry Auchstetter, Business Development Manager at Bodine Electric.

Similarly, when choosing linear guides and systems, compactness is one of the key criteria for AS/RS manufacturers. In shuttle systems, this typically means using telescoping guides on the horizontal axes, which retrieve and replace bins or trays from the storage rack. The application’s bin density strategy – that is, the number of bins that are stacked one behind the other in the storage rack, or the number of “bins deep” – dictates the reach needed by the guide rails, which can be as much as 3 ft for a single bin.

Rick Wood, General Manager at Rollon Corporation says, “Double-stroke telescoping rails are typically preferred, due to the long extended lengths that are needed. And it’s not uncommon to mount two rails on top of each other to achieve the requirements for both the extended length and the retracted length.”

Brian Burke, Senior Product Manager at Bishop-Wisecarver Corporation gives an example of a customer who needed to automate the storage and retrieval of carbon fiber segments that were 40 ft long. DualVee guide wheels and linear guide track were used to create double-extending telescoping conveyor sections that could achieve the required reach while keeping height to a minimum.

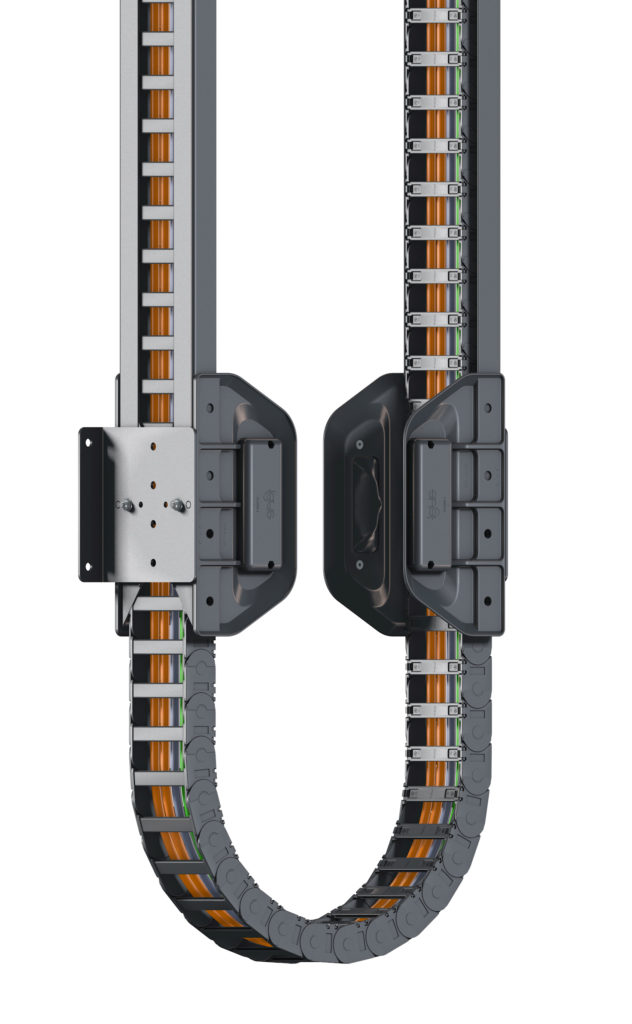

Supporting equipment, such as energy chains, can also be chosen to minimize space. For example, E-chains with a tight bend radius allow the user to select cables that also have a small bend radius, which shrinks the overall height of the chain. Dan Thompson, Product Manager – Energy Chain at igus, points out, “In vertical applications, the E-chain, if left unguided, could sway and potentially break. But guiding structures take up space, so igus has developed a guide tray that is low-profile and sits very close to the E-chain to minimize the overall width of the system.”

Supporting equipment, such as energy chains, can also be chosen to minimize space. For example, E-chains with a tight bend radius allow the user to select cables that also have a small bend radius, which shrinks the overall height of the chain. Dan Thompson, Product Manager – Energy Chain at igus, points out, “In vertical applications, the E-chain, if left unguided, could sway and potentially break. But guiding structures take up space, so igus has developed a guide tray that is low-profile and sits very close to the E-chain to minimize the overall width of the system.”

Another benefit of minimizing footprint is that it often results in lower mass to be supported, moved, or managed, which ultimately results in lower energy usage.

Types of automated storage and retrieval systems

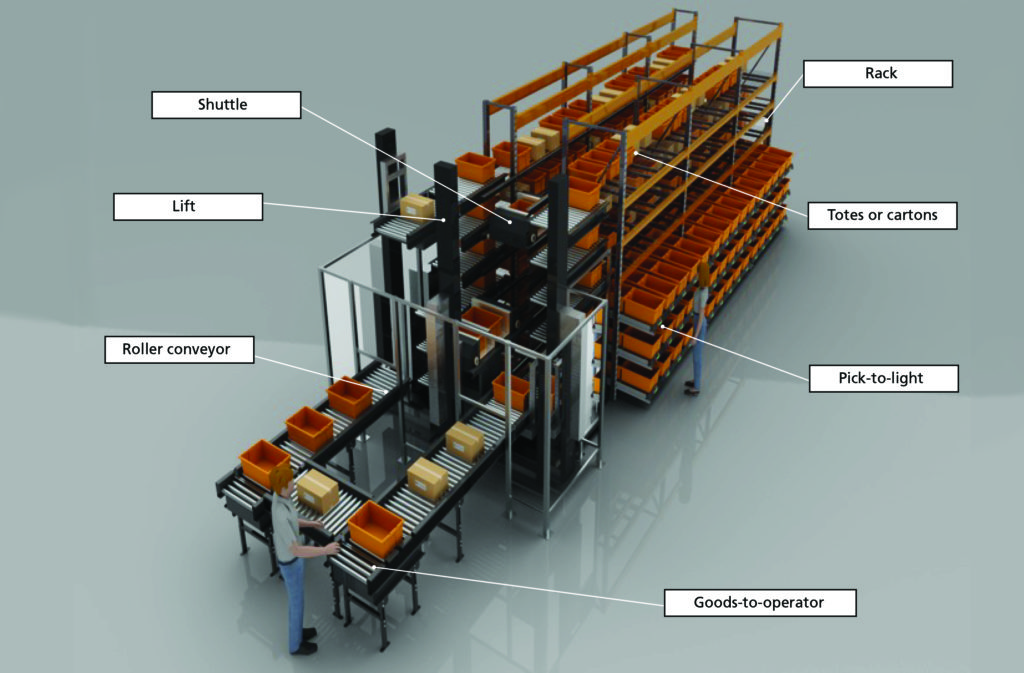

Automated storage and retrieval systems use sophisticated controls to store, retrieve, and deliver materials to specified locations. The Material Handling Industry identifies six main types of AS/RS equipment, which can be grouped into three categories:

1. Fixed-aisle (F/A) storage and retrieval systems are constructed with one or more aisles of storage racking, which are served by a moving structure – often a crane or shuttle – that can reach each storage location and place or retrieve loads with a telescoping arm.

- Unit-load AS/RS: These are generally the largest AS/RS systems, typically used for handling pallets or pallet-sized materials weighing 1000 lb or more.

- Mini-load AS/RS: Rather than handling pallets, mini-load systems handle totes, cartons, or trays weighing less than 1000 lb.

- Micro-load AS/RS: Micro-load systems deal with loads that are typically less than 100 lb, stored in small totes or trays.

2. Vertical lift modules (VLMs) have vertical columns of trays or storage bins in both the back and the front of the module, with a mechanism in the center to automatically insert or extract materials.

3. Carousels are characterized by a series of bins that rotate horizontally or vertically.

- Horizontal carousels: These systems rotate horizontally around a track to position the bin in the picking position.

- Vertical carousels: These rotate vertically and are typically enclosed on all sides to secure the materials being transported. The requested bin or shelf is presented to a window, and products are picked though this window.

Increasing energy efficiency of AS/RS installations

Energy efficiency starts with the selection of individual components and sub-systems. For example, when a product is being retrieved, the vertical axis is held in position for a certain period of time, and as Don Labriola, President at QuickSilver Controls points out, “To maximize energy efficiency, you should choose a motor that is able to hold the vertical load with minimal power.” He adds that another way to improve efficiency is to capture regenerative energy – especially from vertical axes – and feed it back to the power source or store it in battery packs.

Mechanical components typically contribute to energy efficiency by way of lowering the moved mass, and therefore, the inertia of the system. “Vertical lifts that were once driven by chains have migrated to steel-reinforced timing belts and pulleys,” explains Graff of Intelligrated. As AS/RS equipment has evolved, the required speeds and accelerations of the horizontal and vertical axes have increased greatly.

“Chain drives can’t achieve the performance requirements of modern equipment, and belt and pulley systems have the added benefits of lighter weight and lower inertia than chain drives,” says Wood of Rollon.

Other examples of mechanical components that can contribute to lowering energy consumption are E-chains constructed from lightweight plastic and guide rails with an optimized, weight-reduced profile.

“Energy efficiency is important to AS/RS manufacturers because it helps them deliver a better value proposition to their customers,” says Duncan of Schneider Electric.

Maximizing energy efficiency requires not only using components and sub-systems that are themselves energy efficient, but also using those components and systems intelligently. This is best accomplished by monitoring the actual system requirements and comparing those with the expected performance. To this end, Schneider Electric offers a dashboard that allows users to monitor the energy usage of their AS/RS equipment.

With this information, they can adjust the machine’s operation to match the process requirements, thereby improving efficiency. Schneider Electric also offers energy efficiency audits of storage and retrieval systems. For one manufacturer of automated handling systems, an energy efficiency audit, together with hardware and software adjustments to better match the machine’s operation to the required throughput, resulted in energy savings of 15 percent.

Manufacturers: Bishop-Wisecarver Corporation • Bodine Electric Co. • igus • Intelligrated • Oriental Motor • QuickSilver Controls Inc. • Rollon Corp. • Schneider Electric • SSI Schaefer

The advancement of the machines have gone way too far now, this is an incredible article that I ever came across as it provided me with so much information that I was not aware of before, thank you for sharing such great article and taking out time to publish it as well.