Depending on the exact technology, typical linear motors can deliver unlimited strokes and (with feedback) accuracies to ±1 μm/100 mm. Speeds range from inches to 1,000s of inches per second. Semiconductor manufacture and assembly as well as machine-tool applications continue to account for the majority of linear-motor applications.

However, increased focus on efficiency is spurring new applications for linear motors on axes in packaging, material handling, automotive, off-highway, and general automation. That’s because the direct-drive nature of linear motors makes for top efficiency from linear motors (thanks to negligible mechanical losses) as well as fast and precise (or slow and extremely steady) strokes. So in recent interviews, we asked industry experts where exactly linear motors replacing other linear-motion technologies — and other questions about new technologies aimed at further boosting the performance of linear-motor designs. Here’s what they had to say.

William Fang | Engineer • Chieftek Precision USA: Linear motors have far longer life than mechanical linear actuators in short-stroke applications, because they’re not susceptible to wear, shock, and fatigue issues. Linear motors also excel on long-stroke axes. Just consider magnetic-levitation trains, which are essentially linear-motor applications having stroke lengths of many miles.

Much the same way, precision linear motors for industrial applications have essentially unlimited stroke lengths. That’s in contrast with most rotary-to-linear-based designs used in motion-control applications such as leadscrews, which have speed limits due to their tendency to whip or thrash beyond a given value. So linear motors are increasingly applied on long-stoke axes where such screws or rack-and-pinion sets might get used despite limitations — on robotic seventh-axis systems, for example. Here, linear-motor designs can be built and installed in 1-m sections – a level of modularity impossible with leadscrews.

In one recent installation, a 16-m-long robotic seventh axis based on one long linear-motor installation automates a large assembly area of an LCD production facility. This makes for reduced wiring and (where linear-motor axes move battery-powered tools) no exposed cables or cable carriers at all.

Do you offer design engineers any value-added services? Do these integrators design the mechanical build (including the gearmotors or linear motors) or the setup of controls and networking?

Peter Zafiro • LinMot USA: Our partners — often high-tech distributors — add a lot of value. These folks are leading the charge towards offering more engineering services … especially when it comes to machine integration.

Most of the houses were historically electrical distributors, so originally worked in “pipe and wire” utility projects … and then expanded scope to electrical machine integration. But of course, mechanical and mechatronics integration is necessary for machine builds as well. That’s why many distributors are stepping up and keeping mechanical and electrical engineers on staff to support customers in design work … and those are the partners that we’re really gravitating towards, as they solve a lot of problems for smaller to medium size OEMs specifically.

What do you see design engineering most wanting to outsource?

Zafiro • LinMot: Not all OEMs these days have copious motion-engineering experience staff … and of course, they don’t do motion applications every week; they might engage in motion design once or twice a year. They need outside expertise to come in and help. That’s a fit for us (and our distributors) because linear motors are direct-drive systems requiring highly precise calculations up-front — including calculations of what the axis is going to move … and where … and how fast … and with what motion profile. After the initial work, the OEM can modify future designs based on those first calculations. We provide the application expertise and the OEM can take it from there.

What are other benefits of positioning based on linear motors?

Fang | Chieftek Precision: Another benefit of direct-drive positioning based on linear motors is the way in which it allows processes to occur directly on the production line. Reconsider LCD-panel manufacture: Here, overall plant yield in increased when post-production processes detect (and save for commercial sale) nearly perfect panels. Linear motors move probes about flagged LCDs for pixel verification. Then the linear-motor-based system moves other tools such as cutters and lasers over the LCD’s pixels needing remanufacture — those for which the controlling transistor is stuck on, for example.

Here, the system cuts that transistor off and then replaces it. Or in other cases, the station might fix or replace the electronic traces. Such stations in an LCD production facility increases yield — leveraging the sub-micron positioning accuracy of linear-motor-based designs.

Another electronics example is in the manufacture of smartphone covers. Here, linear-motor-driven laser cutters help make their tapes and holes for screw assembly very accurate.

What are some new linear-motor-related technologies available now … and on the horizon?

Patrick Wheeler | Product manager • Aerotech: One trend in drives is to fit more capability per square unit of back panel space. Many customers are working towards either making systems compact (taking up less floor space) or getting more capability out of a given design footprint. So our approach is to integrate multiple features in all-encompassing tightly-packaged electronic drives … which capture motor control, encoder feedback, home and limit-switch feedback, laser outputs, and multiple general purpose I/O in a single electronic device. These drives have been very well received by the market.

Fang | Chieftek Precision: At the recent ATX West in Anaheim, Calif. we previewed our new TC1-D servodrive (we’ll soon be releasing to market) along with stock 8-A and 20-A (1.5 kW and 5 kW) TC-1 Series drive products we already sell to complement linear-motor applications. Our TCB-1B Series drive was also on display — what I would classify as Chieftek’s 1.5-generation drive.

This drive supports all standard encoder formats — with connectivity and functionality for sin/cos, resolver, Tamagawa Seiki, Nikon, Mitutoyo, EnDat, and bi-directional synchronous serial interface (BiSS) feedback. The inclusion of both sin/cos and resolver support is unique.

The exceptionally compact single-axis TC1-D dc driver we previewed runs on 48 V with a continuous output of 30 A. In fact, theoretical output is far higher … but Chieftek is currently executing careful burn-in testing and verification on the drive to ensure total reliability. Target applications for these drives include electric vehicles, robot arms, or integration directly into linear stages for embedded control. It has all the same encoder features of our TC1-B Series drive … which is in sharp contrast with comparable drives currently on the market that are limited to a few digital feedback options. Because the drive design relies on a single microcontroller, the circuitry is also compact for a board of about 2 x 2 in.

The aim is to sell the drive in three versions: as naked core modules to be integrated into users’ motherboards; as units for use with a breakout board using JST connectors (for integration onto robotic arms, for example); and a more traditional version with a case and bigger connector case in the so-called “bookshelf” case to install in a traditional control cabinet.

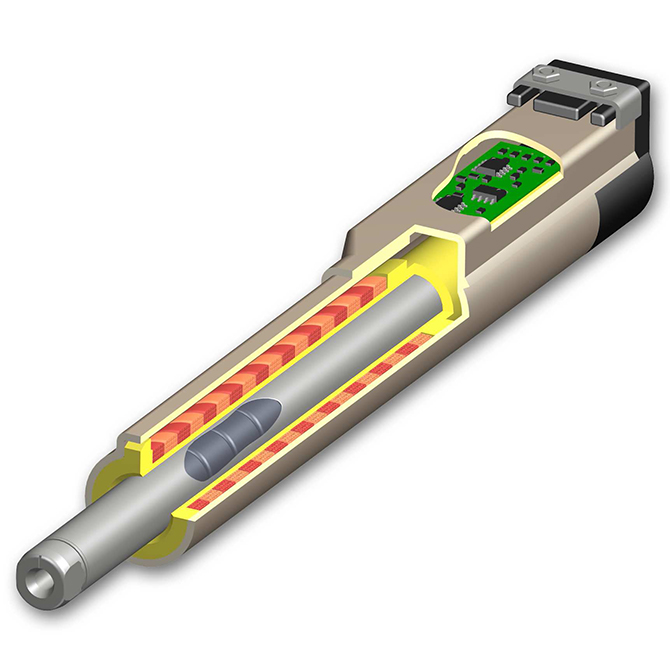

Zafiro • LinMot: We use temperature sensors on the windings of all our linear motors — so users can get top output performance … without risk. The problem with designs that employ thermistors or switches is their lag time. This lag time between actual winding temperature rise, and when the temperature increase is sent to the control system for corrective action is the issue. In contrast, our linear motors’ temperature sensors track actual temperature in real time — and our drives run algorithms to immediately reduce current to the motor during rapid temperature rises. Yes — in some cases that means the axis won’t complete its stroke in the preset amount of time … but the system prevents motor overtemperature faults and even motor destruction. Basically, our system won’t let you destroy the motor.

What’s the point of tracking motor-temperature information beyond preventing motors from burning up under extreme conditions?

Zafiro • LinMot: We support a lot of designs destined for extreme environments with our IP69K stainless solutions – engineers just can’t automate with other technology. Consider certain cutting applications using our motors in pairs at 90% duty cycle. Here, temperature control of the motor lets users vary motor speed and cutting speed; depending on the rather inconsistent material entering the cutting station (and its density and other qualities) motor temperature may rise. When the change affects the actual cutting process, modifications lower system throughput until the challenging piece clears. Of course, this is one very cool application; most applications just involve going from point A to point B — as in reject applications and pick-and-place applications.

More and more end users consider data important – exactly the point of Industry 4.0 data for trend analysis. Recording how certain product was made under one set of conditions … and a product 1,000 pieces later was made under another set of machine conditions. Of course, the millionth piece made by a given piece of equipment won’t be identical to the first piece. There’s always something changing in the environment (such as humidity and temperature) and all the mechanical parts in the equipment (such as bearings) slowly wear. Degradation of machine components becomes evident by the time that machine outputs its millionth piece … and clear trends (if recorded) can indicate when preventive maintenance is prudent. This is a game changer for running an efficient manufacturing process!

Where is stainless steel overkill? Doesn’t it make the linear motor harder to cool?

Zafiro • LinMot: Applications where engineers want to use stainless-steel motors abound. Our stainless motors are laser welded, so completely sealed — and nothing can get into them. But indeed … stainless is a very poor conductor and requires special motor design features to allow heat dissipation. Liquid cooling is a leading approach here. However, some applications can’t accommodate the subcomponents for liquid cooling … and others can’t bear the added cost. These may need to use different technology … and maybe something that isn’t IP69K. That’s the issue: In these cases, there are few options to build a truly clean machine design. There may need to be a stainless skin around the motor drive system and possibly sealing (always problematic to severe cleaning environments) to prevent protruding components from allowing contamination of the housing interior.

Cleanable machine designs would certainly help reduce the number of beef, cracker, and lettuce recalls like the ones we’ve had recent years.

Zafiro • LinMot: Many applications are moving quickly towards clean and cleanable machine builds, so end users can feel comfortable about direct food contact and use any number of cleaning solutions without issue. I believe the recent romaine-lettuce recall was the first time since 2005 the entire industry stopped production — because they couldn’t pinpoint where tainted product originated and where the contamination occurred. It took more than a week to figure it out. Completely cleanable equipment that actually withstands aggressive cleaning and washdown will allow operators to rest easy. The only challenge here is ensuring good cleaning practices. Now, many operators are stuck: “I can’t clean this because I’d destroy my drive and motor components.” Better machine cleanability is going to become more and more the norm … and more companies like ours will provide components that achieve exceptional results in these very tough environments.

Leave a Reply

You must be logged in to post a comment.