Moving coils have been around for many years. Now though, market pressures are causing the technology to rapidly evolve and gain in use. This technology competes most directly against pneumatic drives and moving-magnet rotary motors.

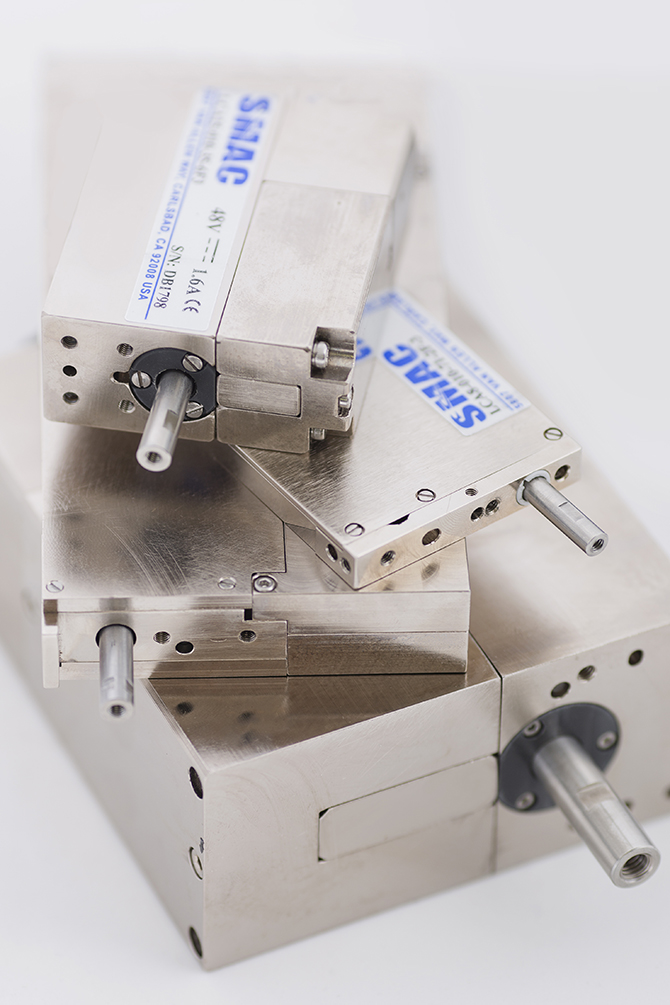

By Ed Neff • President | SMAC Moving Coil Actuators (MCA)

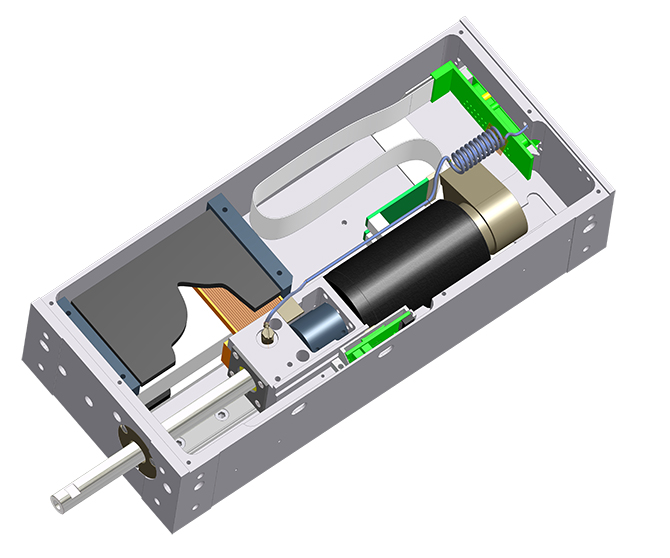

Moving coil technology works in both rotary and linear motors. The technology has been around for a long time. Recall that within the actuator are permanent magnets generating a magnetic field; a moving coil resides in that field. Passing current through the coil generates traverse motion of it and the output shaft or shuttle. The force of that output is proportional to the coil’s turns ad the magnetic flux within the actuator (both constants) as well as the current … so more current through the coil increases output force.

In brush-type rotary servo motors based on moving coil technology, the brush provides the means for current to get to the coil. In contrast, single-pole linear motors — often called voice coils — are at the heart of many speakers.

Read the first installment of this Technical Notes series: When did the most common linear-actuator options come about?

The introduction of high-strength neodymium magnets has greatly expanded the applicability of moving-coil actuators in motion applications, as actuators with these magnets output high force (or torque).

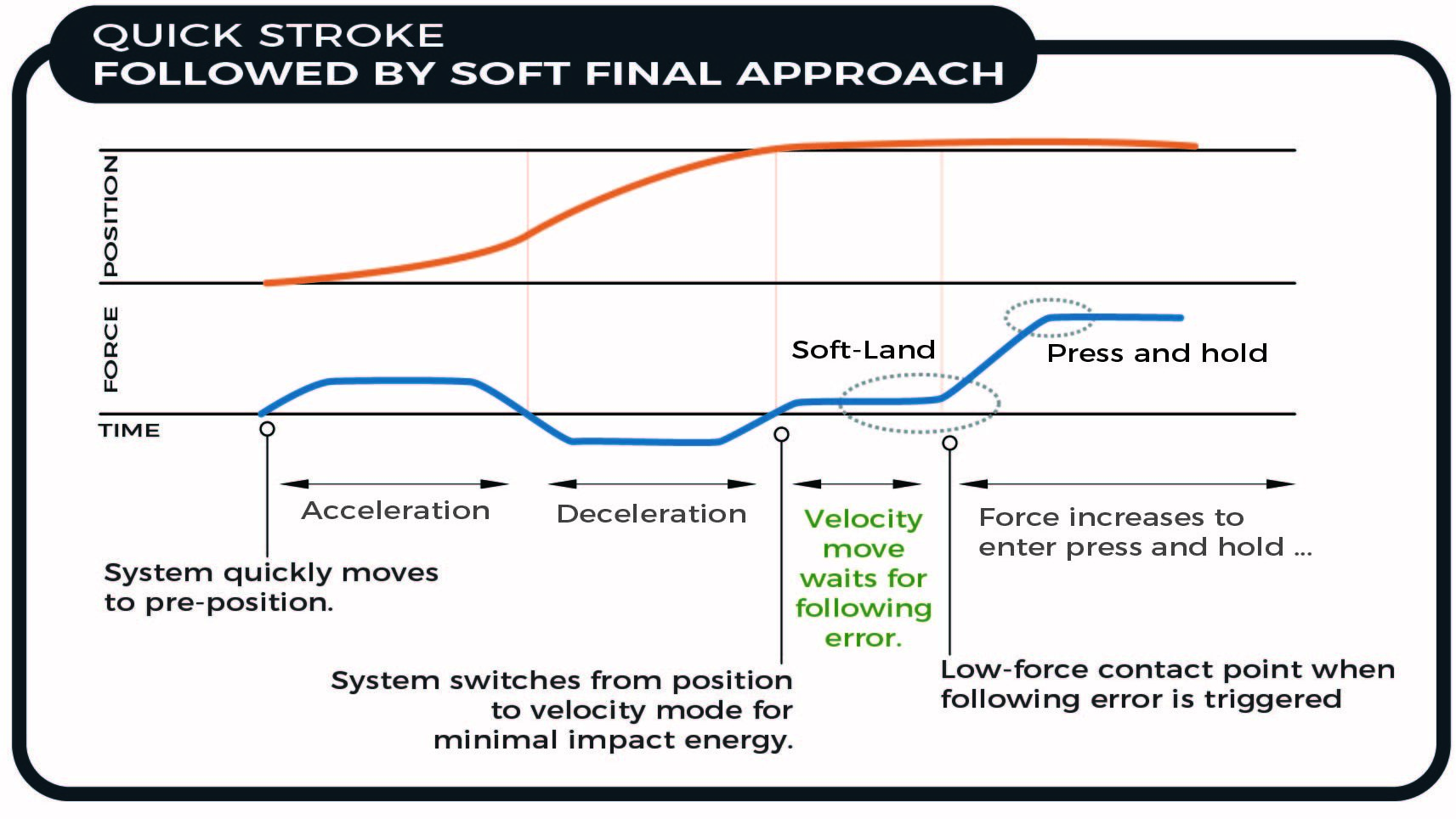

The light moving mass of their coils make the actuators excel in many industrial applications because it allows for high cycle rates – to twice that of pneumatic or ball screw actuators. In addition, moving-coil actuators have:

• Long cycle life — to 10 times that of pneumatic or ball screw linear actuators

• High repeatability over each cycle — to 10% the variance found in pneumatic devices

• Programmable force and torque output

• The ability to provide the movement for very slow speed applications.

Two factors restrict the technology’s wider implementation.

Cost: Moving coil linear motors (and their accompanying motion controllers) have until recently cost five times more than a pneumatic cylinders and valves of comparable size … and triple that of stepper-motor-based ball screw actuators.

Current input: Moving-coil actuators require a mode to get current to the coil — via brushes for rotary actuators and flex cable for linear variations. The former wears out and the latter is limited to strokes of about 500 mm or shorter.

Even so, this is changing — with moving-coil actuators seeing an uptick in use for several reasons related to simplicity and cost effectiveness:

1. Encoder cost has dropped to below $15 … mostly due to the development of low-cost chips by a number of makers and the development of low-cost plastic scales.

2. The cost (and size) of motion controllers and amplifiers have also dropped significantly. Volume pricing is now approaching $100 per axis and will continue to decrease. This is due in part to the increased use of servo motors in automotive applications.

3. Coil manufacturing cost is also rapidly dropping. This is due to the advent of new printed-coil technology and all the substantial benefits it imparts:

- No soldering

- Resistance variation to 1% of that of wound coils

- Very low-cost tool-up of new designs — with a typical expenditure of about $5,000

- Ability to print coil shapes that are impossible to wind

- Ability to integrate flex cable, encoder, and main connector into a printed flex circuit (as a way to reduce part count and assembly cost)

4. Another factor shrinking the price of certain moving-coil actuators is the way in which some manufacturers reduce the cost of the magnets by cutting long magnets to size and magnetizing them in-house.

5. Certain manufacturers can also replace linear guides with flexures for short strokes (of less than 30 mm) … to leverage the fact that flexures can cost less than $1.

Today, moving coil servo actuators with built-in controller amplifiers are priced at around $350 (for volume orders) and are therefore comparable in price to actuators that incorporate ball screws … though are still twice to three times the cost of pneumatic systems. That said, prices are projected to drop another 35% as the factors listed above begin to affect the market.

The other factor restricting the technology’s wider implementation is its need for a brush or flex cable. Here a solution could be on the horizon. University of Eindhoven researchers have demonstrated wireless power transmission on moving coil rotating servo motors. It’s technically feasible to apply this not only to rotary moving coil motors but to linear actuators as well. The main hurdles here are cost and the size of the power-transmitting components. But advances continue … so expect the appearance of this technology in the market in the near future.

Leave a Reply

You must be logged in to post a comment.