Recently I made a day trip from Cleveland to the Pittsburgh area for a facilities tour with a leading motion-component supplier. The Parker Hannifin Electromechanical and Drives Division offers engineering expertise as part of their industry support — and designs and produces motion-control systems to meet myriad application requirements. These range from miniature stages for life-science applications to overhead factory-floor gantries.

Recently I made a day trip from Cleveland to the Pittsburgh area for a facilities tour with a leading motion-component supplier. The Parker Hannifin Electromechanical and Drives Division offers engineering expertise as part of their industry support — and designs and produces motion-control systems to meet myriad application requirements. These range from miniature stages for life-science applications to overhead factory-floor gantries.

The supplier’s specialty is satisfying demand from OEMs and end users for design services and pre-integration of motion subsystems as well as complete machines.

The facility is set in the hills of Irwin, Pa., and began as a precision machine shop in 1969.

Today, Parker’s Electromechanical and Drives Division supplies everything from electronic-propulsion systems for hybrid vehicles to multi-ton laser-guided machine centers. More after the jump.

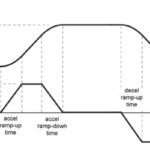

During our visit, we spent some time with Ben Furnish of the Parker Hannifin Electromechanical and Drives Division. He explained how the industry and Parker have evolved in recent years, and what the Parker Selectable Levels of Integration program means to OEMs and design engineers. Machine builders can buy components from Parker; or they can buy bundled technologies; or they can buy complete systems. Here’s more on that from Furnish — including his explanation of how his team serves the different order types with engineering support:

Of course, Parker connects with OEMs and end users in other ways. So while at Parker, we also spoke with Travis Schneider, product manager of high precision mechanics.

Take a look at what Schneider had to add with specific product examples:

After interviews with Furnish and Schneider, we sat down with Jeremy Miller (product manager — linear mechanics) to get his insight into why there’s increasing migration from fluid power to electromechanical technologies. Read highlights from Miller’s comments and listen to what else he had to say:

Strength on the manufacturing floor:

Profiles of the Parker team

As with any production facility, Parker’s Irwin location relies on its plant personnel to bring excellence to their end products.

Perhaps it’s my own Rustbelt sentimentality here, but our last portion of the day’s visit — to meet with a few of these stars on the Parker Hannifin team — was especially fulfilling.

Read on for the profiles of Rick Veverka, Bob Germanoski, and Brian Handerhan who work at the Irwin facility … Profile of Rick Veverka

Leave a Reply

You must be logged in to post a comment.