When discussing bearing life, what comes to mind for most engineers is the standard L10 bearing life equation. But this equation was developed for bearings with rolling balls. (A similar equation exists for bearings that use rollers rather than balls.) For plain bearings, which have no rolling elements, determining the suitability of the bearing for a particular application requires an examination of technical and environmental factors, coupled with empirical testing and the experience of the manufacturer.

Of the factors to be considered, the most important are the pressure imposed on the bearing (P) and the bearing’s velocity (V). These are combined to develop a PV rating, which represents the highest combination of load and speed under which the bearing can operate properly.

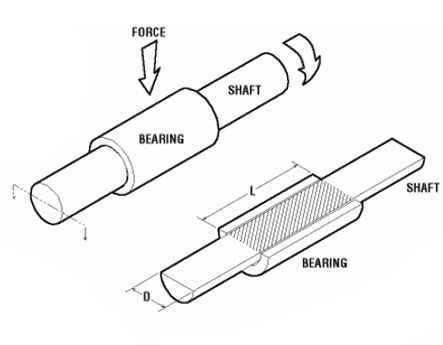

Pressure is determined by dividing the maximum load (force) on the bearing by the supporting area of the bearing.

![]()

Where:

P = pressure (N/mm2 or lb/in2)

F = load on bearing (N or lb)

A = area (mm2 or in2)

For a round bearing riding on a shaft, the supporting area is simply the length of the bearing times its inner diameter.

![]()

Where:

l = bearing length (mm or in)

d = bearing inner diameter (mm or in)

One of the critical performance characteristics of a plain bearing is its ability to dissipate heat. Heat affects a bearing in two ways. First, it can degrade lubrication or the lubricating properties of the bearing. But more importantly, heat can change the clearances between the bearing and its housing or between the bearing and shaft. The result is increased friction, greater wear and reduced bearing life.

A bearing’s PV rating is related to heating caused by friction in the bearing, and takes into account multiple factors that contribute to the system’s ability to transfer heat away from the bearing, including:

- thermal conductivity of the bearing and the shaft (or rail)

- difference between the maximum bearing temperature and the ambient temperature

- thickness of the bearing

- coefficient of friction between the bearing and the shaft

While the bearing’s maximum PV value is a key criteria, and often the starting point, for choosing a linear bearing, it’s important to note that the PV rating isn’t the only indicator of a bearing’s suitability for an application. The individual pressure and velocity values should also be kept within the maximum allowable limits, noting that some bearings perform well in high-load/low-speed applications, while others perform better in high-speed/low-load conditions. And environmental factors are a major consideration when choosing the best bearing and shaft materials for an application.

Is it a “plane” bearing or “plain” bearing? The terms are often used interchangeably, but the American Bearing Manufacturers Association uses the term “plain” bearing.

Feature image credit: igus

Leave a Reply

You must be logged in to post a comment.