In this article, we answer the common question “what is torque?” Although torque refers to rotational motion, it is a fundamental concept in linear motion applications. Rotary motors produce torque, and when this torque is transmitted to a drive system – such as a screw, belt and pulley, rack and pinion, or chain and sprocket – it’s converted to linear motion.

What is Torque?

Torque is the rotational equivalent of force. Specifically, it is a force exerted at a distance from an object’s axis of rotation. In the same way that a force applied to an object will cause it to move linearly, a torque applied to an object will cause it to rotate around a pivot point. The pivot point is known as the axis of rotation, and the perpendicular distance of the force from the axis of rotation is known as the moment arm. This is why torque is also referred to as moment of force.

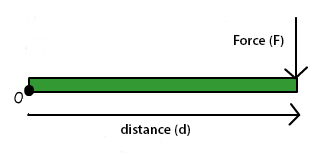

In the simplest scenario, the applied force is perpendicular to the axis of rotation. In this case, torque is simply the product of the force and its distance from the axis of rotation:

![]()

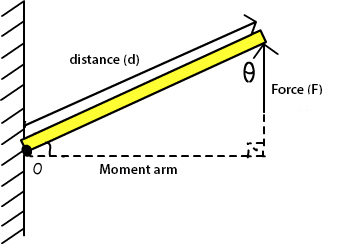

But in many applications, the force does not occur perpendicular to the axis of rotation. In this case, the angle of the force must be taken into account to find the length of the moment arm:

![]()

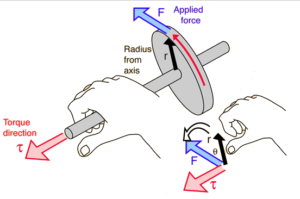

Torque is commonly denoted with a capital “T,” but the correct symbol is the Greek letter tau, “τ.” When torque is referred to as a moment of force, the symbol “M” is used.

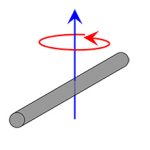

Torque is a vector quantity, meaning it has both magnitude and direction. The direction of torque can be found by using the right hand rule. Curl the fingers of the right hand from the direction of d (or r, for radius) to the direction of F. When this is done, the thumb points in the direction of the torque.

When sizing a linear motion application, it’s important to understand the torque requirements and limitations of all the components in the system. The required torque is one of the key parameters for sizing a motor. In most applications, both peak torque (which typically occurs during acceleration or when holding a load) and continuous, or RMS, torque must be considered. In addition, shafts and other components that transmit torque along the drive train – such as gearbox shafts, couplings, and screw shafts – must also be able to withstand the application’s peak torque.

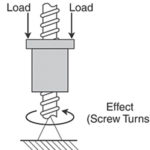

The terms “torque” and “moment” are often used interchangeably. While the two are similar, torque produces rotation around an axis, while a moment is a force applied at a distance that does not produce rotation. For example, a screw has an axis of rotation, so a force applied at a distance from this axis will cause the screw to rotate. A profiled rail guide, on the other hand, is fixed and does not rotate. A force applied perpendicular to the guide will produce a moment, but does not induce rotation.

Leave a Reply

You must be logged in to post a comment.