Bill’s electric actuator drive must operate in factory conditions with dust, moisture, heat and vibration. But Bill’s main problem is with electrical noise; there’s enough in his environment to disrupt actuator control signals and cause erratic movements. Electrical noise–random fluctuation in an electrical signal–is present in all electronic circuits. When the amplitude of these fluctuations […]

Get your custom conveyor fast

Designing a conveyor system to your specific application needs continues to get easier. Glide-Line ™, a developer of material handling equipment, offers a versatile multi-strand panel and pallet-handling conveyor system. The company offers configuration tools that streamline the design experience, ensuring a Glide-Line conveyor will meet your exact specifications. Plus, with the conveyor systems’ modular […]

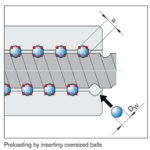

How to specify a ball screw

Ball screws are available in a range of types, styles, and sizes. A few tips, though, will help you match the right ball screw with the right application. 1. You will have the best success with specifying a ball screw if you know the following information about your application: Duty Cycle—the cycle rate, dwell times, […]

Electric current damage — How bearings fail Part 2 of 6

Recently we examined how corrosion contributes to bearing failure. Now we’ll examine electric current damage. Random electrical currents, which come from multiple sources, such as wiring, insulation, static electricity from operating equipment, and so on, will damage bearings. The damage usually appears on the surface of rings and rolling elements and is similar to that produced by electric […]

Corrosion — How bearings fail Part 3 of 6

Recently we examined how surface distress contributes to bearing failure. Now we’ll examine corrosion. Corrosion occurs primarily when either lubricants fail or the seals have failed and the bearings have been exposed to water or corrosive liquids. Corrosion can lead to early fatigue failures through the rust that forms in the bearing, especially if rust occurs in […]

Distress in bearings — How bearings fail Part 4 of 6

Recently we examined how smearing contributes to bearing failure. Now we’ll examine surface distress. Even with the best of manufacturing methods, no surface is perfectly smooth. In bearings, proper lubrication helps smooth out the roughness between bearings and raceways and other parts that interact. If the amount of lubrication is insufficient, or the lubricant is reaching the […]

Smearing — How bearings fail Part 5 of 6

Recently we examined how brinelling contributes to bearing failure. Now we’ll examine bearing smearing. Just a reminder: Factors that contribute to bearing failure include material fatigue; operating with a heavier loading than specified; inadequate or unsuitable lubrication; careless handling; poor sealing; and bearing balls or rollers installed too tightly, with insufficient internal bearing clearance. Each of these contributors leaves […]

Brinelling and why bearings fail — How bearings fail Part 6 of 6

Recently we examined how wear contributes to bearing failure. Now we’ll examine indentations, sometimes referred to as brinelling. Just a reminder, there are a number of causes that contribute to brinelling, including: • Material fatigue • Operating with a heavier loading than specified • Inadequate or unsuitable lubrication • Careless handling • Poor sealing • Bearing balls […]

Mechanical wear — How bearings fail Part 1 of 6

Today, bearing manufacturers can reliably predict the operating life of bearings, which makes it easier to specify the right bearing for an application. Bearings do fail, if for no other reason than components do not operate forever. A number of causes contribute to failure, including material fatigue; operating with a heavier loading than specified; inadequate or […]

Kinetic Gear Sculpture Illustrates Mechanical Motion

Designed primarily to showcase mechanical motion during a trade show, this new kinetic gear sculpture from SDP/SI illustrates mechanical motion principles. It was designed and arranged by Andrea Davide, a New York-based artist who specializes in creating unique metal sculptures. Check out the video; this is a good way to show mechanical motion principles, whether […]