Recently we examined how brinelling contributes to bearing failure. Now we’ll examine bearing smearing.

Just a reminder: Factors that contribute to bearing failure include material fatigue; operating with a heavier loading than specified; inadequate or unsuitable lubrication; careless handling; poor sealing; and bearing balls or rollers installed too tightly, with insufficient internal bearing clearance.

Each of these contributors leaves known clues on the bearings or the races, so it is fairly easy to determine what happened. However, multiple contributors can be at play in each cause, so it’s useful to have an understanding of each contributor and each cause. The primary types of damage are:

• Mechanical wear

• Indentations and brinelling

• Smearing

• Surface distress

• Corrosion

• Electric current damage

Other forms of damage show up as flaking or cracks.

Proper lubrication is so critical to bearing operation. If you’ve been following this series, you can see that insufficient lubrication contributes to most of the above listed types of bearing damage, including smearing.

If a bearing is operating under insufficient lubrication and heavy load, smearing can occur. In smearing, metal is removed from one surface of the bearing and deposited onto another. The temperature in the bearing is often high enough to harden the transferred metal to the second surface. Visually, smearing looks as though one of the surfaces was “torn.” The resulting stress in the local area may contribute to cracking or flaking.

Smearing can occur is several places within a bearing:

–On the ends of cylindrical rollers: here smearing can indicate that the roller bearing is under a thrust load. Applications involving thrust loads are generally not suitable for this type of bearing.

–At the roller end-guide flange interfaces: a clear indication of insufficient lubrication, often between the flanges and roller bearings. In some cases, it could mean the bearing is under a heavy axial load in one direction over a period of time.

–At the ball entry points into the load zone: an indication of insufficient lubrication to handle the ball movement speed or an indication of sudden or excessive acceleration.

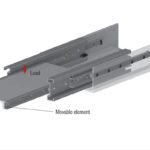

–On roller bearing surfaces (raceways and the rolling elements): In some operations, roller rotation is inhibited in the unloaded zone, which lowers the rotation speed when rolling elements are in the loaded zone. Therefore, the rollers can undergo sufficiently rapid acceleration to cause smearing. For raceways, the problem usually arises as a result of improper mounting. It’s important that the rings be rotated properly.

–In the raceways of thrust ball bearings: Smearing here indicates that the rotational speed may be too high in relation to the loading. As centrifugal force pushes the balls to the outer portion of the raceways, sliding can occur. The smearing will appear as diagonal streaks at the outer part of the raceways.

Other causes of smearing can be attributed to careless handling, blows, and excessive pressure to the wrong ring during mounting or installation.

Leave a Reply

You must be logged in to post a comment.