Recently we examined how wear contributes to bearing failure. Now we’ll examine indentations, sometimes referred to as brinelling. Just a reminder, there are a number of causes that contribute to brinelling, including:

• Material fatigue

• Operating with a heavier loading than specified

• Inadequate or unsuitable lubrication

• Careless handling

• Poor sealing

• Bearing balls or rollers installed too tightly, with insufficient internal bearing clearance

Each of these contributors leaves known clues on the bearings or the races, so it is fairly easy to determine what happened. However, multiple contributors can be at play in each cause, so it’s useful to have an understanding of each contributor and each cause. Primary types of bearing failure appear as:

• Wear

• Indentations

• Smearing

• Surface distress

• Corrosion

• Electric current damage

Other forms of damage show up as flaking or cracks.

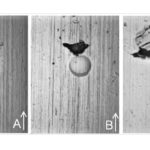

Indentations (brinelling) on bearings for motion designs

If a bearing develops indentations or dents, they are often labeled “brinell” marks, and are an indication of a bearing that was either improperly mounted during installation, one that is supporting an excessive load, or a bearing that is contaminated with debris.]

There are generally two types of brinelling: true and false. Each has a different cause.

True brinelling indicates that the load on the bearing is greater than the elastic limit of the ring or bearing material. It is one of the more common causes of bearing failure. According to some manufacturers, self-aligning ball bearings are susceptible to this issue.

False brinelling looks similar to true brinelling, but occurs through vibration, not necessarily excessive load.

In transportation, vibration can cause rollering elements to move, leaving indentations along the raceways, which looks similar to the damage from excessive load. The application of a light thrust load from springs or rubber pads before a bearing is transported can prevent such damage.

During operation, vibration can squeeze out much of the lubricant between the rolling elements and the raceway, resulting in a surface finish that resembles brinell marks, but that will not permanently indent either contact surface. In some situations, you can increase the angle of bearing rotation to redirect the forces causing the vibration.

Once brinell marks develop, bearing vibration increases and will eventually affect the loads the bearing can handle as well as the speeds it can operate at until the bearing finally fails.

To prevent true brinelling during mounting, apply slow and even pressure to the right part of the bearing. Exert force against the ring being mounted, that is, apply the pressure against the inner ring. If you are mounting a bearing in a housing, apply pressure against the outer ring.

To prevent true brinelling that occurs as a result of excess load, specify a bearing with enough capacity to handle the desired load.

To prevent false brinelling, conduct regular maintenance checks and ensure sufficient lubrication.

A third cause of brinell marks occurs when foreign particles manage to make it into the bearings. These particles do not need much mass or hardness to damage the bearings because during operation, the rolling elements distribute them throughout the raceways. Proper maintenance and sufficient lubrication can help prevent this damage.

For more information on rotary-bearing lubrication, wear, and failure prevention, go to linearmotiontips.com baby-sister website bearingtips.com. Here are just a few related articles from that resource.

Turning the volume down on ball bearing noise in your motion system

In this interview bearingtips.com speaks with NMB Field Applications Engineer, Rich Picard about bearing vibration, noise …

… and the things to look for when specifying bearings for your motion system.

NKE — Application analysis for lubrication of rolling bearing

NKE — Application analysis for lubrication of rolling bearing

About 40% of all premature bearing failures are caused by lubrication problems.

Daniel Stöckl and Klaus Grissenberger, application engineers at NKE Austria GmbH, show you how to prevent lubrication issues before they happen.

Timken’s 14 step procedure for bearing analysis

Timken’s 14 step procedure for bearing analysis

Timken engineer’s give a step-by-step process for an accurate and complete analysis when investigating any bearing damage or system breakdowns.

Three bearing killers and how to stop them: Part 1

Three bearing killers and how to stop them: Part 1

Bearing failure can grind your operations to a halt, resulting in significant lost time and production.

Here are the first three of six common factors that can cause bearings to fail, and what you can do to prevent them.

Three more bearing killers and how to stop them: Part 2

Three more bearing killers and how to stop them: Part 2

Part two of the two-part bearing-killers article above.

Most bearing manufacturers offer information on brinelling as well — including its causes and prevention: Garlock Bearings • www.ggbearings.com | igus • www.igus.com | • Pacamor Kubar Bearings • www.pacamor.com | • NSK • www.nskamericas.com | SKF • www.skf.com/us | Timken Bearings • www.timken.com

Leave a Reply

You must be logged in to post a comment.