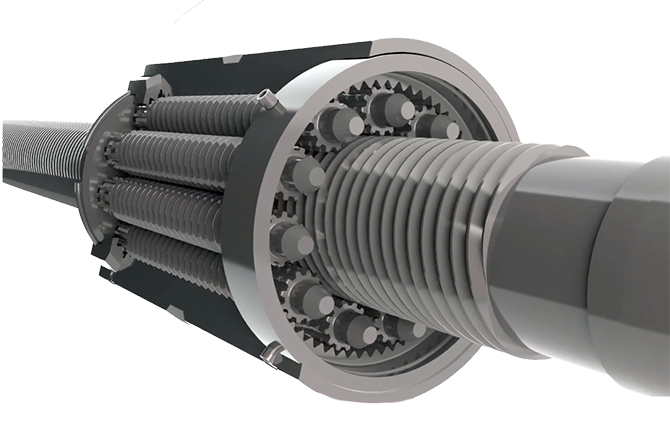

Screw assemblies that use rollers as the load-carrying element come in several varieties, with the most common being the traditional planetary roller screw, which provides high load capacities and very high rigidity, capable of outperforming ball screw and hydraulic actuators in some heavy-duty applications. But another type of roller screw — the recirculating roller screw — offers high load capacity and rigidity, but with very fine leads for applications that require positioning with high resolution.

Recall that planetary roller screws use a screw, nut, and cylindrical rollers that all have matching threads. The rollers also mesh with geared rings at the ends of the nut, allowing them to spin on their own axes while they revolve around the screw, so that each revolution of the screw shaft advances the nut by a distance equal to the lead of the thread. With many more contact points than ball screws, the primary benefits of the roller screw design are higher load capacity and better rigidity.

Image credit: Tolomatic

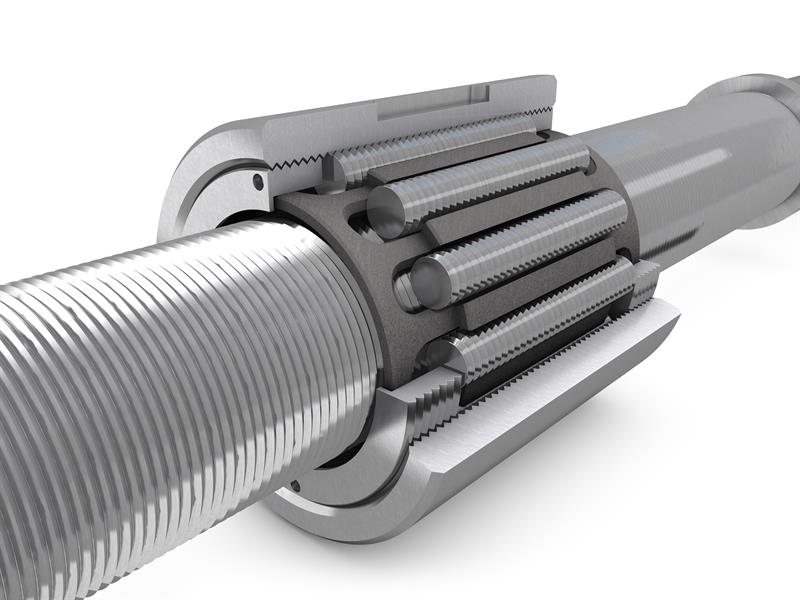

Recirculating roller screws also use a threaded screw and nut, but the rollers are grooved rather than threaded. In other words, each roller has a series of individual grooves which lie perpendicular to the roller’s axis. This means that as the rollers revolve around the screw shaft, they’re displaced axially within the nut, along the length of the screw, by a distance equal to the lead of the screw and nut thread.

Image credit: Ewellix

The behavior of the rollers within the nut is a key difference between planetary and recirculating roller screw designs. In the traditional planetary design, the threaded rollers simply advance along the screw shaft and do not move axially within the nut. In the recirculating design, the rollers only have grooves — not threads — so they do move axially within the nut, and therefore, need to be recirculated.

The most common recirculating roller screw designs use a cage with slots that are slightly longer than the roller length, allowing the rollers to rotate and to move axially within the nut. After a roller makes one revolution around the screw, cams at each end of the nut disengage the roller from the screw shaft and shift the roller into a groove in the nut body, returning the roller to its initial position within the cage, but advanced axially on the screw by an amount equal to the screw lead.

This video from Rollvis shows the operation of a typical recirculating roller screw design, using a cage that holds the rollers and allows them to move axially within the nut.

Another recirculating roller screw design forgoes the use of a cage. In the cage-free design, when the rollers complete one revolution around the screw, they disengage from contact with the screw, but not with the nut. Cam rings on each end of the rollers guide the rollers into the nut’s axial groove, which is threaded, and ensure consistent pressure between the rollers and the nut.

The primary benefit of recirculating roller screws is the availability of very fine leads. Most manufacturers offer recirculating roller screws with leads as small as 1 mm, and some even offer fractional-millimeter leads. These small leads provide high resolution while also requiring lower input torque for transmitting loads. In contrast to traditional planetary roller screws —which are typically used in applications that require very high thrust forces and rigidity, such as pressing operations — recirculating versions are ideal for applications that require very fine, high-precision motion, such grinding equipment and optics alignment.

Leave a Reply

You must be logged in to post a comment.