A linear ball bushing riding on a round shaft is often compared to a radial ball bearing, with the bushing acting as the outer race of the bearing and the shaft acting as the inner race. But in linear bushing assemblies, the surfaces of both the ball and the shaft are spherical, so contact between them is, theoretically, a point, meaning the resulting pressure between them would be infinite.

A linear ball bushing riding on a round shaft is often compared to a radial ball bearing, with the bushing acting as the outer race of the bearing and the shaft acting as the inner race. But in linear bushing assemblies, the surfaces of both the ball and the shaft are spherical, so contact between them is, theoretically, a point, meaning the resulting pressure between them would be infinite.

In real-world conditions, however, the surfaces of both the ball and the shaft experience some elastic deformation, resulting in an area (rather than a point) of contact between them. But this contact area is small, and the pressure between the ball and the shaft can still be extremely high and sufficient to initiate spalling and failure.

Because of the pressure created by the load-carrying balls, the hardness of the shaft plays an important role in determining the life of the assembly. Simply put, the harder the shaft surface, the better it can resist permanent deformation and avoid premature failure.

The hardness of bearing surfaces is typically quantified using the Rockwell C scale, abbreviated “HRC.”

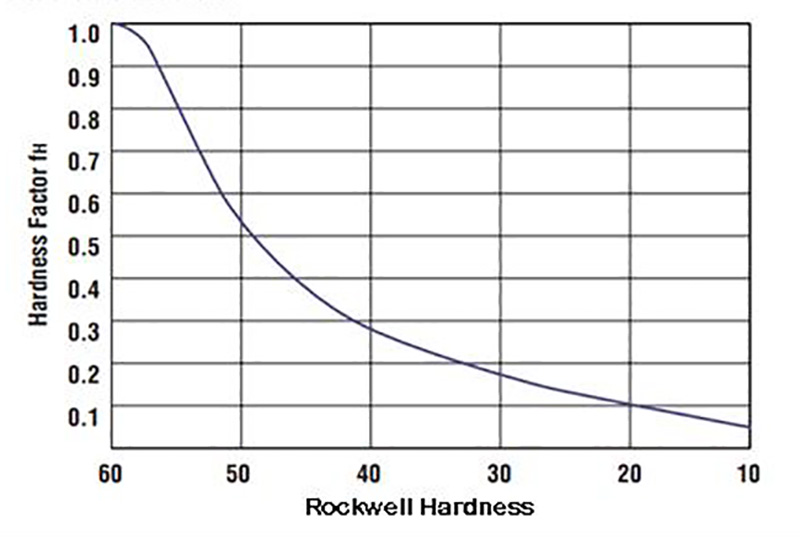

To account for shaft hardness, life calculations for linear ball bushings include a shaft hardness factor (fH), which is applied to the dynamic load capacity (C). The shaft hardness factor is 1.0 for a shaft with hardness of HRC 60, but decreases for lower hardness values.

Image credit: Thomson Industries Inc.

As shown in the life equation below, the shaft hardness factor (fH) is cubed, so it has a significant effect on the bearing life. In other words, if a linear ball bushing is used on a shaft of HRC 60 (fH = 1.0), it will have eight times (8x) the life of a bushing that is used on a shaft of HRC 50 (fH = 0.5).

![]()

Note that stainless steel shafts, which are commonly used in linear ball bushing assemblies, can have hardness ratings as low as HRC 54 (fH of approximately 0.7), depending on the grade of stainless steel. So linear ball bushing assemblies that use stainless steel shafts can have significantly lower life expectancies than those using standard HRC 60 shafts, even if all other operating parameters are the same.

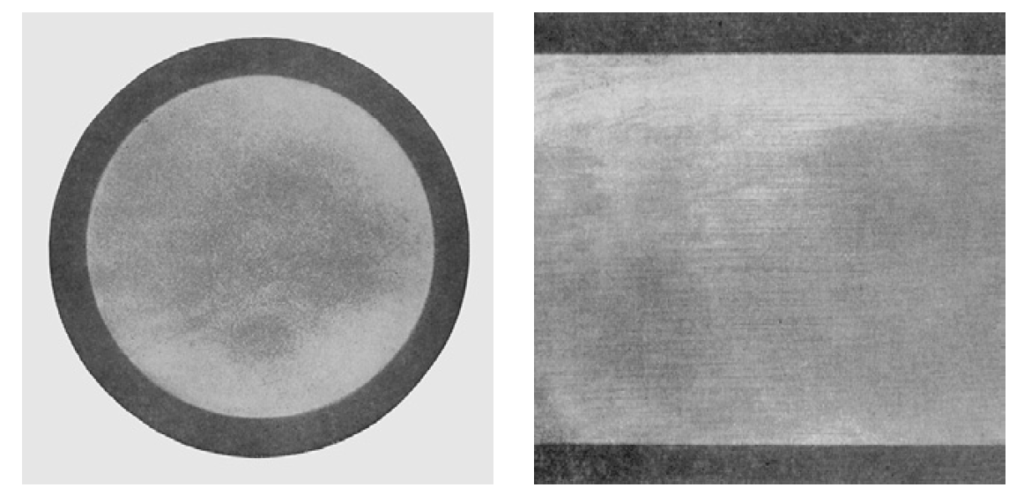

Linear bearing shafts are typically hardened via induction hardening to a precisely controlled depth of anywhere from a fraction of a millimeter to several millimeters. The depth of hardening depends on both the diameter of the shaft and the shaft material, with larger diameter shafts requiring a larger hardness depth since they carry higher loads and experience higher pressures and stress concentrations.

Image credit: Bosch Rexroth

Prior to machining, shafts that have been hardened require annealing — which involves controlled heating and cooling of the material — to reduce their hardness and make them workable. And it’s important to remember that high operating temperatures can reduce a material’s hardness. This is why the bearing life calculation for linear ball bearings often includes a temperature factor (ft), which de-rates the bearing’s dynamic load capacity for temperatures exceeding 100° C.

Check out this shaft material selector tool from LM76 for descriptions of different shaft materials and their suitability for use with linear ball bearings.

Leave a Reply

You must be logged in to post a comment.