Pneumatics (and compressed air) are indispensable in many industrial applications. They’re cost-effective and easy-to-understand technologies that are rugged enough to run in even very challenging environments. The problem is that some facilities can spend up to 30% of their electricity bill on generating compressed air. Because pneumatic actuators for linear motion (which have been an option to design engineers since WWII) run on compressed air, they’re one type of component that can degrade the overall efficiency of an automated operation. well-understood, cheap, and suited to harsh environments.

Depending on the expansiveness of a factory, arrays of pneumatics can require numerous compressors … or a complicated reticulation system. After all, a reliable level of pressure must be maintained — or the pneumatic actuators will work poorly or not at all.

But air leaks do happen … and they’re expensive. According to one compressor technology company, a leak in one component costing 15¢ per kW-hr can add well over $2,000 to the yearly power bill. With a single point of failure (such as air leakage at a degraded seal, for example) the air pressure of the whole plant will drop … and operations will be less than optimal.

Another problem is noise. “When working in or visiting a factory, you’ll usually hear a lot of noise,” explains ANCA Motion product manager Heng Luo. “That’s one big advantage servo-controlled linear motors have over pneumatics” that they’re much quieter adds Luo.

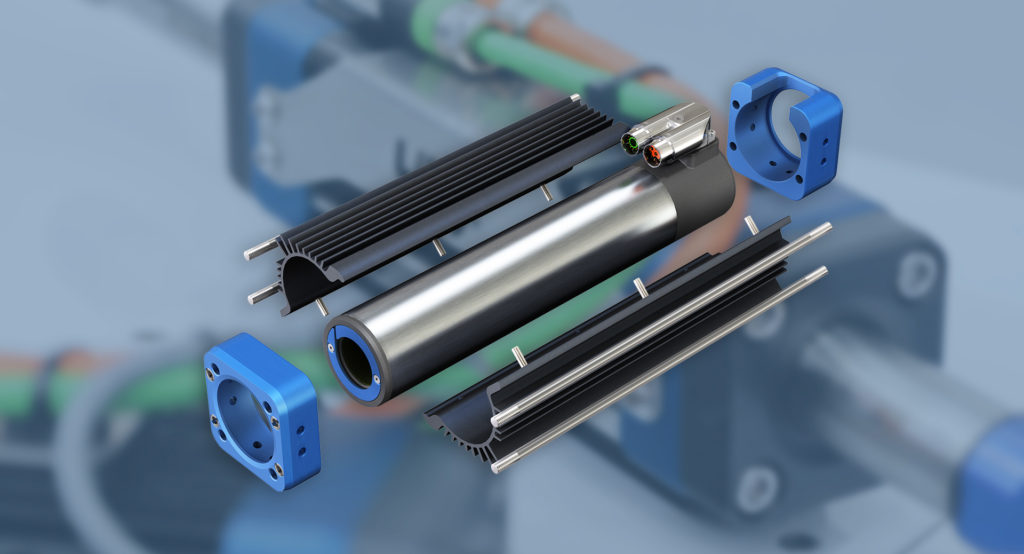

Linear actuators such as those base don rotary motors (with rotary-to-linear screw components) as well as true tubular linear motors are newer than pneumatic as well as hydraulic linear actuation. Though somewhat more complicated to integrate and control, these are electric-motor-based linear actuators are preferred for certain applications. Instead of a piston in a cylinder driven by compressed air or an incompressible fluid, tubular linear motors use magnetic flux to create motion. They have a higher upfront costs than pneumatics, but offer vast benefits in aspects including accuracy, cheaper operating costs, and flexibility.

In addition, linear actuators based on traditional pneumatics can move quickly and forcefully from one point to another (and hydraulics quicker and more forcefully still for the same size) but with little positional control along the stroke.

One option for motor-based actuation is ANCA Motion’s LinX M-Series offers 10-μm resolution as well as velocities to 10 m/sec as well as:

• Maximum acceleration of more than 30 g

• An integrated position sensor with precise positional control

• Continuous force of 90 to 160 N

• Peak force to 1,200 N

The estimated payback period (return on upfront investment) for the M-Series electric linear actuators is also much shorter than that for pneumatic cylinders of comparable form factor and mounting design— typically around 18 months.

Another advantage of -Series electric linear actuators is ease of reprogramming. In one recent application, an end user’s forming machine substituted LinX motors for pneumatics to move a cutting bed. Changes for different workpiece lengths could take six to eight hours for the painstaking recalibration of air pressure. Such adjustments now are a quick change in servo drive parameters — a matter of seconds. The improved positional control has boosted throughput by 50% with the massively improved precision for higher throughput.

ANCA Motion’s linear motors were originally developed for sister company ANCA CNC Machines’ FX Linear and MX Linear tool and cutter grinder machines. ANCA is a leader in CNC tool grinding technology, with a series of world firsts since beginning in 1974. In fact, the LinX M-Series Tubular Linear Motor has a failure rate of less than 0.03% … and robust support is offered through an international network of 125 engineers in strategic locations. For more information, visit this deep link on motion.anca.com.

Leave a Reply

You must be logged in to post a comment.