Engineers building linear motion systems can use ground-up DIY approaches or purchase complete turnkey solutions. Here we explain where each tactic is most profitable.

By John Brokaw and Kent Martins | Valin Corp.

How should designers pick between building linear-motion designs in-house or purchasing pre-engineered assemblies? What is there to consider when determining the best design approach? The answers to these questions all begin and end with the details of the engineering process and the machine for which an assembly is being designed. All approaches to linear-motion builds have advantages and disadvantages — and so (as with most engineering) incur design tradeoffs.

Planning ahead with realistic budgeting and looking at the long-term functions of a machine can provide machine builders and end users with the most profitable setup.

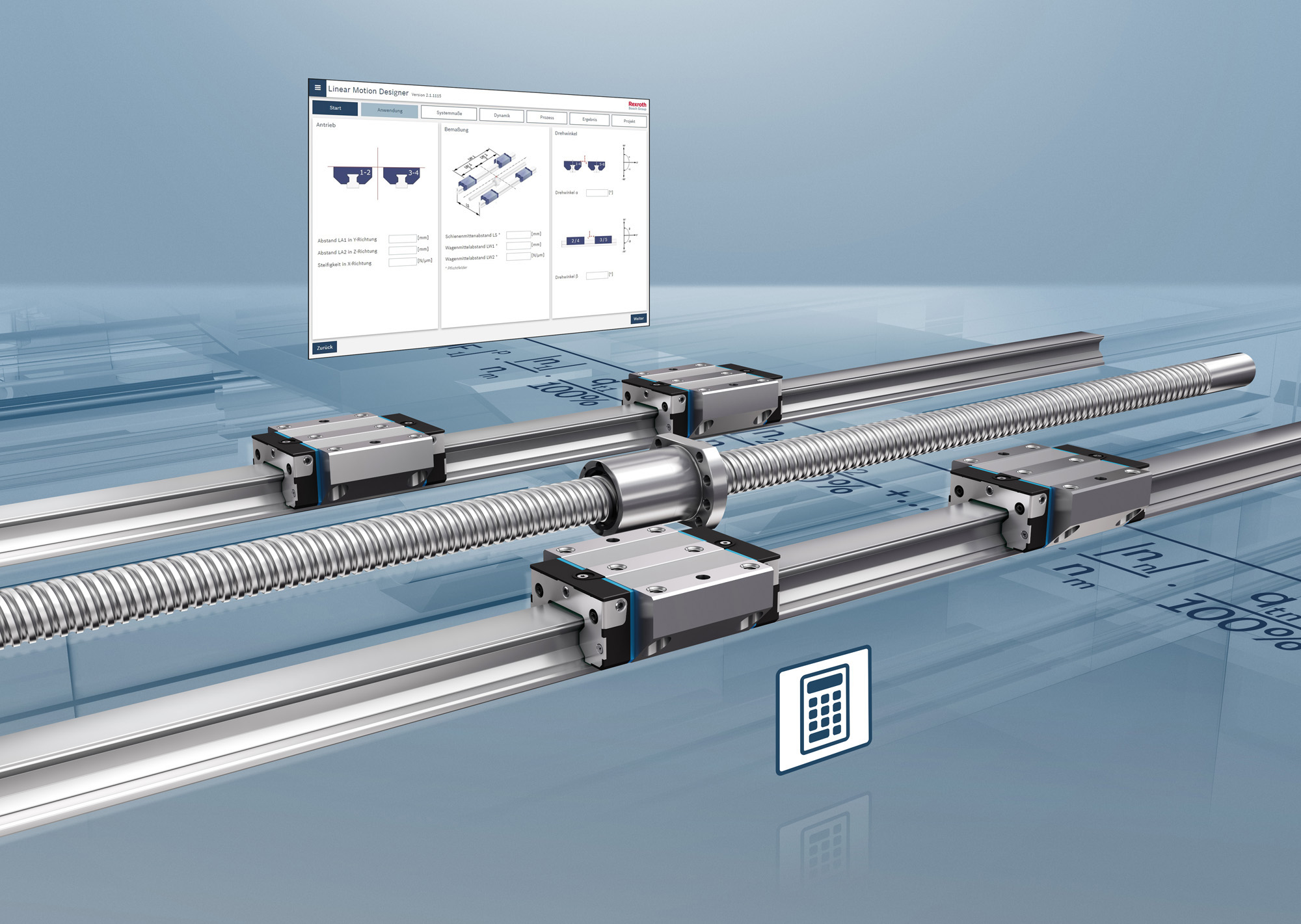

DIY linear-motion solutions from scratch

Complete customization can be perfect for some plant operators and a nightmare for others. What are the benefits? Well, the DIY approach of linear motion design offers the option to customize almost every detail of a machine. Designers can tailor components to the exact needs of the end process because they are basically creating the system from scratch.

But if this sounds like an expensive design approach that requires a decent amount of time to complete, it is. One advantage of DIY motion designs is maximizing labor on the backend … But even here, a plant must ensure it has the engineering power to execute.

Having engineering talent in-house is key for the DIY build approach because of the cost of labor and time it takes to create the system. Hiring out non-recurring engineering to complete the job is an option, but it comes with risks. When using an outside engineering source, the level of control over the design can be slightly diminished. Outsourcing can also create issues down the line if a motion design must be modified but the outside engineering team originally hired is suddenly unavailable.

What’s more, it’s difficult to replicate previous designs that weren’t created in-house. To what kind of process would this level of customization apply? It really depends on the size of production of the machine’s end use. DIY linear-motion builds excel when they’re destined for machines that will be mass produced, or if the market place doesn’t offer a setup to satisfy the end-use requirements.

For machines to be mass produced, OEMs can realize some economies of scale by buying only components they need in volume. Sometimes OEMs can also buy components that are less costly than purchased motion systems that exceed end-use needs. Where the marketplace doesn’t offer a motion design to meet end-use requirements, sometimes the optimal choice is a one-off solution. For example, a custom linear actuator might help meet accuracy and precision requirements or dimensional and environmental parameters. In fact, customization is a major factor when considering DIY linear-motion design builds.

Hybrid linear designs for the best of both worlds

For design engineers looking to drive moderate to minimal system customization, the hybrid engineering approach is the best course of action. Hybrid setups are exactly what they sound like— a little bit of DIY paired with a complete setup. Pre-engineered setups make it easy to mix and match parts of the system without requiring unworkable engineering effort to create and execute the design.

With components that are predefined and have documented capacities, all a customer must worry about is the final assembly of the pieces. Hybrid linear-design approaches also come with warranties for their components, which can be a reassurance for customers. If there’s a problem with a part and the company doesn’t have specialized technicians to fix it, they can go to the manufacturer for data and information to help resolve the issue.

There’s no overarching best method for designing a linear motion system. What’s best for a machine user depends on their process, operations timeline, and available manpower.

One of the main disadvantages of hybrid setups is obviously a lower level of customization. Engineers are limited to designing by the manufacturer’s standard sizes and width, which can be challenging in some processes. Hybrid linear-design approaches are best for applications that may need a mismatch of manufacturers. If an OEM demands different, specific brands for one or more items, the hybrid design is really the only option. Although different manufacturers are being used for specific items, each one carries its own specifications and warranty.

If a specific subcomponent is defective or wears out prematurely, the designer also has some recourse on replacement. If the end user has damaged their system in some fashion, a replacement part can be bought off the shelf in some cases. If the designer wants to change the stroke or speed, it’s also easier to make changes to hybrid linear-design approaches because the system specifications are all available through the manufacturers.

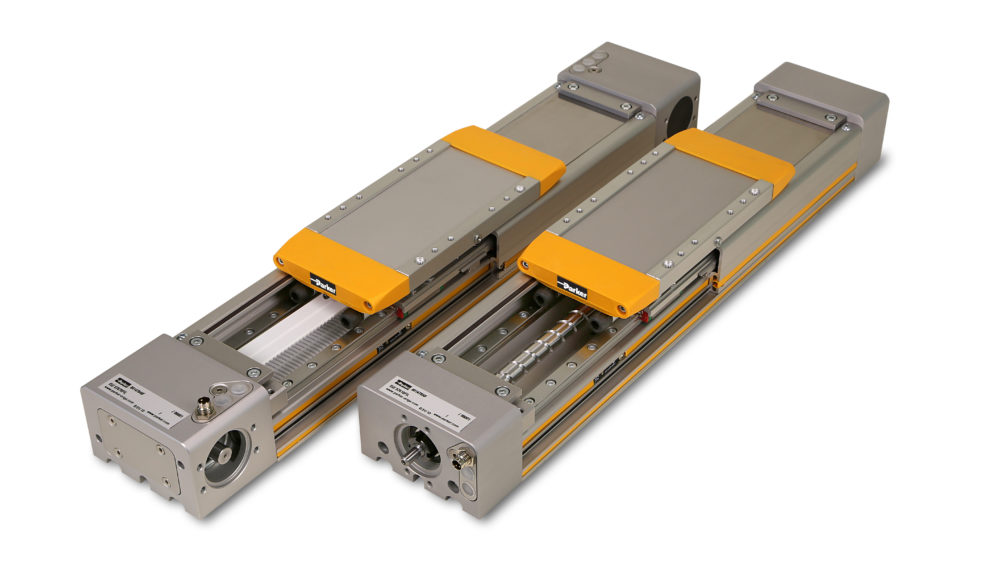

Turnkey linear-design approaches for complete setups

Complete turnkey setups are comparable to going to a restaurant for dinner instead of cooking at home. The only decision a machine builder must make is choosing what they want. Offered linear designs are complete and ready to be implemented without additional design time. Another huge advantage of this approach to linear-system design is that the capacities of the setup are all specified by the manufacturer. For example, a machine builder can order parts prespecified to perform in cleanrooms or in environments that need explosion-proof components. With complete turnkey setups, the component manufacturer knows exactly what the capabilities are. Plus unlike linear systems built with a DIY approach, there’s little chance that engineers will mistakenly choose components to meet unnecessary design parameters.

One downside to pre-engineered linear-motion designs is that they aren’t going to be perfectly tailored for every process. Because the parts are already made and measured, there’s very little room for customization for a designer (aside from choosing what part fits best). That’s why this engineering approach is best used by machine builders that don’t have enough engineering talent on staff to complete a design in-house.

As with linear-motion designs built with a hybrid approach, turnkey builds also offer specifications and warranties for how the system components work together. They are great for replacement parts and components, but what makes them suitable for designers are the elements of single-source setups and having to deal with only one vendor. If something goes wrong with the design, the operator only must approach that one vendor to resolve it.

Linear-motion system (monetary and time) budgets

When choosing an engineering approach that’s appropriate for a design, machine builders must ask themselves a lot of questions about the process for which they are designing. Before making any final design decisions, engineers should also know where they are in the design cycle and what their overall budget will be. Here, the project’s time budget is also an important factor. Usually, the time required to build for an application is about the same for all three design approaches … though turnkey linear designs can generally be engineered a bit more quickly. No matter the approach, engineers need to present manufacturers with a solid idea of how long they have to implement what they need.

About the authors: John Brokaw and Kent Martins are senior application engineers at Valin Corp., a leading setups provider for technology, energy, life sciences, natural resources and transportation industries. Valin offers personalized order management, onsite field support, comprehensive training and applied expert engineering services using automation, fluid management, precision measurement, process heating, filtration and fluid power products. For more information, visit www.valin.com.

This Article gives a clear view of showing the difference between DIY and turnkey builds