In part 1 of this series on bearing speed, we looked at the factors that limit the speed of linear recirculating bearings. In this segment, we’ll look at the factors that limit the speed of linear plain bearings.

Linear plain bearings operate with sliding contact between the two bearing surfaces, so the limitations encountered with rolling elements aren’t a factor in plain bearing performance. But that doesn’t mean plain bearings have unlimited speed capabilities. Instead, plain bearing speed is primarily dependent on heat generation.

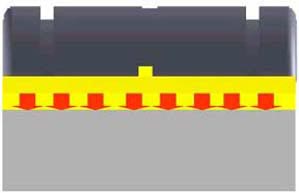

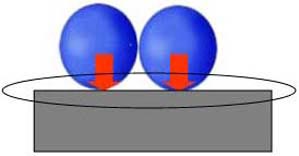

For a linear plain bearing, there is a large contact area between the bearing and the shaft or guide. This allows plain bearings to carry heavy loads, but it also causes them to generate more heat than a bearing with less contact area, such as rolling element bearings. This heat has two effects on the bearing: it can degrade lubrication or the lubricating properties of the bearing, and it can change the clearances between the bearing and its housing or between the bearing and the guide. Both scenarios result in increased friction, greater wear, and reduced life.

Image credit: igus

Image credit: igus

PV factor

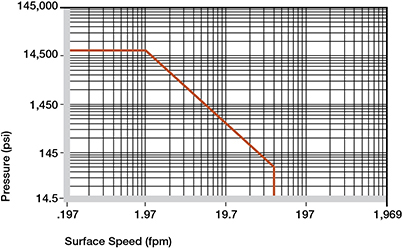

Heat is generated by movement, and the amount of heat generated depends upon the load on the bearing, the bearing’s speed, and the coefficients of friction of the materials. This is why linear plain bearings have what is referred to as a PV rating (PV = pressure x velocity). The PV rating depends on the system’s ability to transfer heat away from the bearing. It designates the highest combination of load and speed under which the bearing can operate properly.

Thus a linear plain bearing operating at a high speed will have a reduced load-carrying capability, and a plain baring carrying a high load will have a reduced speed capability. Note, however, that a plain bearing also has a maximum load capacity rating and a maximum velocity rating. So it’s not possible to carry an infinitely small load and travel at an infinitely high speed, or vice-versa, even if the PV rating would be acceptable.

Image credit: igus

Although the PV rating is a key indicator of a plain bearing’s maximum speed, bearing material also plays an important role.

Material influences

Coefficient of friction has a significant influence on a bearing’s PV rating, and in turn, its maximum speed. The higher the friction coefficients of the materials, the more heat will be generated as the surfaces slide across one another during operation. The choice of materials, of course, determines the coefficient of friction.

Plastic bearings have insulating properties, meaning that heat is retained in the bearing, causing the material to expand and friction to increase as the bearing operates. Aluminum guides, however, have good thermal conductivity and can help transfer heat away from the bearing. Plain bearings made of metal (typically bronze) are often lubricated with oil in high-speed applications. This lubrication reduces friction between the sliding surfaces and aids in cooling. The construction of composite bearings make them good at transferring heat away from the inside of the bearing.

Feature image credit: Federal Highway Administration

Leave a Reply

You must be logged in to post a comment.