In power transmission applications, there are two primary types of screw drives: those that use recirculating balls or rollers, for applications that require high rigidity, excellent positioning accuracy, and high duty cycles, and those that rely on sliding contact, for applications that require corrosion-resistance, self-locking operation, and customizable nut designs.

The second category — screw drives with sliding contact between the nut and the screw shaft — are referred to as lead screws, Acme screws, or trapezoidal screws. And although these names are often used interchangeably, they actually refer to different screw geometries and dimensions.

Here’s a breakdown of the different types of sliding contact screws and what the terms “lead screw,” “Acme screw,” and “trapezoidal screw” really mean.

Lead screws

The most commonly used of the three terms, “lead screw” simply refers to a type of power screw that relies on sliding motion between the nut and the screw shaft. There are two variations of lead screws: those with square thread forms and those with trapezoidal thread forms.

Lead screw designs for power transmission almost exclusively use trapezoidal threads, which are easier to manufacture and have higher load capacities than screws with square threads. Trapezoidal threads, however, do have higher friction, and therefore, lower efficiency than square thread forms.

A power screw is a screw that transmits power by converting rotary motion into linear motion. Lead screws and ball screws are types of power screws.

Acme screws

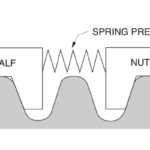

As mentioned above, lead screws for power transmission use trapezoidal thread forms. But the trapezoidal thread design can have a thread angle of either 29° or 30°, meaning there are two versions of trapezoidal lead screws.

The first version — referred to as an Acme screw — has a 29° thread angle and is manufactured in inch dimensions. Acme screw sizes are typically specified by the screw shaft diameter and the threads per inch, or TPI.

Image credit: Roton Products, Inc.

Fun fact: Acme screws were developed in the mid-1800s to replace square thread screws. The name “Acme screw” came from an employee of the Acme Screw Machinery Company in Cleveland, OH, which manufactured multi-spindle lathes. (See pages 13-14 of this scan of American Machinist Magazine from 1985.)

Trapezoidal screws

Trapezoidal screws are also lead screws that use a trapezoidal thread form, but trapezoidal screws have a thread angle of 30° and are manufactured in metric dimensions. The size of a trapezoidal screw is designated by the screw shaft diameter and the pitch of the screw threads. Trapezoidal screws are sometimes referred to as “metric lead screws” or “metric Acme screws.”

Refresher on screw thread designations

Pitch is distance between adjacent threads on the screw shaft.

Threads per inch (TPI) is the number of threads that can be counted in one inch of the screw. Pitch and TPI are the inverse of one another.

Lead — typically used in ball screw nomenclature — is the linear distance traveled per revolution.

Very important and useful information