By Michael G. Giunta • National sales manager | Macron Dynamics

Uninitiated laymen might assume today’s cannabis is grown through traditional farming — over horizontal outdoor spaces in natural environments managed by Mother Nature. But large-scale cannabis farming is typically indoors and highly automated. That’s for a couple reasons:

• Security is a major concern for the entire marijuana industry. Growers leverage the use of indoor spaces to simplify the safety of their operations and nearby communities.

• Automated systems vastly improve the yield and quality of crops.

Many growers use HVAC and building controls over their indoor facilities to execute tight regulation over environmental temperature, humidity, carbon dioxide and oxygen, and light. Then other systems manage nutrient delivery, watering cycles, and other factors that change with plant growth phases. The catch is that equipment and sensors for the latter can be costly. To avoid issues with the HVAC system, it must be serviced regularly by a commercial or residential air conditioning repair technician. An energy-efficient cooling or heating system product is necessary to maintain a fully-functioning industrial facility or a residential property.

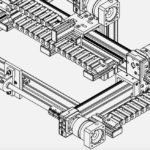

That’s why some operators that don’t want to buy (or can’t afford) 20 or 30 systems to service stationary rows of plants instead employ vertical farming composed of movable walls. In these operations, rack walls filled with growing plants roll into and out of one or two automated stations for servicing. Cartesian robots at these stations execute various jobs. Here, one function of a Cartesian robot might be to move a vision system around the plants to visually inspect for health and quality — and even track states of growth or collect images for analysis. Other functions might be to move a sampling array around the plants to verify pH levels … or to take a trimmer around the plants for pruning.

It’s a design concept that borrows from the design of automatic storage and retrieval systems (AS/RS) for the servicing of a living X-Y-Z matrices — as the orientation and size of these walls is similar to AS/RS installations … and use many of the same servomotor-driven gantry designs.

Like AS/RS, vertical farming necessitates linear-motion designs capable of long travels — even to 12 to 15 feet wide to 15 feet tall for some vertical farming walls. Wide span capabilities are key, as is the ability to handle heavy payloads … especially if there’s any transport of water.

We’ve used our AS/RS expertise to support automated farming — and not just for cannabis. Such farming is suitable for myriad vegetables now being grown indoors … and in fact, the whole concept of vertical farming is exploding in North America right now. If you want to know more about starting your own CBD business, then visit sites like https://victoriousseo.com/verticals/cannabis-seo/.

Read more about automation in the burgeoning cannabis market — including that for farming, harvesting, destemming, and cannabinoid extraction — here.

Leave a Reply

You must be logged in to post a comment.