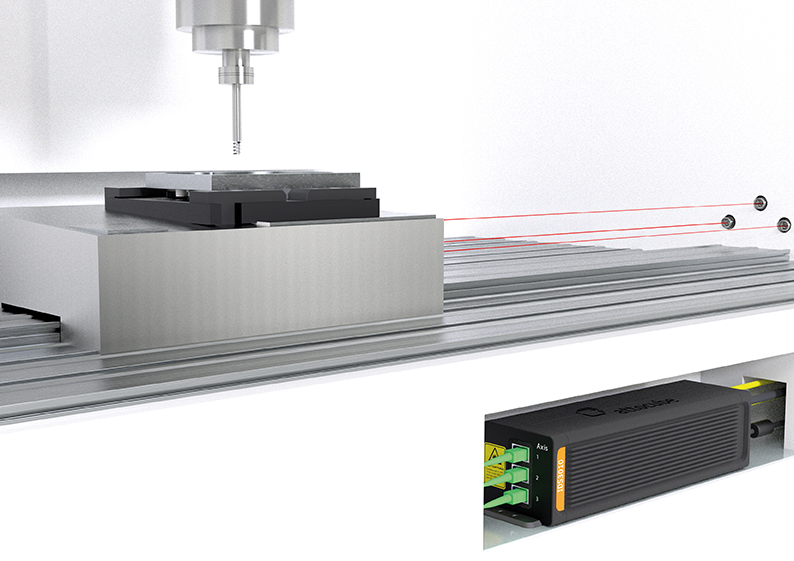

The IDS3010 from Munich-based attocube systems AG, a wholly owned subsidiary of Wittenstein SE, brings a new dimension to high-performance engineering precision. The sensing system is accurate to one-billionth of a millimeter and measures target distances up to 30 meters away. According to company officials, this interferometric sensor easily surpasses the performance of conventional glass scales and other available sensor technologies in terms of precision, speed and industrial suitability.

The IDS3010 is reportedly the first such product that combines exceptional interferometric precision with a compact size.

The unit is a contactless interferometric sensor which enables highly precise measurements of positions and motions. It provides 10-12 m position resolution—in other words, one picometer or one billionth of a millimeter—over working distances of up to 5 meters. If fitted with suitable sensor heads, it can perform measurements over a 30-meter distance.

#LinearSensing accurate to one-billionth of a millimeter — #attocube @WITTENSTEIN_SE • @WittensteinUS Click To TweetThe IDS3010 measures directly on the target, for example a workpiece, tool or machine component. Inherent or mounting-related measurement errors due to backlash, wear, deformation, thermal expansion or other influences—which are intrinsic to indirect measuring glass scales as well as inductive displacement sensing systems—are completely eliminated. Stationary or moving targets are sensed at velocities of up to 2 m/sec with a data acquisition bandwidth of 10 MHz. That means a measurement containing all relevant information related to position or movement is generated every microsecond.

The IDS3010 is designed as an optical, multi-channel measuring sensor. Up to three miniature sensor heads can be connected via glass fiber cables to the compact basic unit, which measures just 19.5 × 5 × 5 cm, to simultaneously measure positions and motions in up to three axes. The sensor heads can be supplied with optics for different types for measurements on all kinds of materials and surfaces such as glass, plastic, ceramic, aluminum, copper or steel. Customized sensor heads — for example, made from tungsten or sapphire — are available for particularly complex measurement tasks.

The device has an integrated web server, so sensor alignment, initialization and configuration can be controlled, adapted and monitored remotely from any location. Likewise, it is suitable for Industry 4.0 applications. A broad spectrum of real-time interfaces and protocols lets position data be transmitted easily to CNC controllers or RTOS computers. The sensor is also compatible with different fieldbuses and standard industrial networks like CAN open, Profinet, Profinet RT or EtherCAT, letting engineers integrate it into large or complex systems.

Industrial-grade interferometry opens up innovative applications, remarked Wittenstein officials. Such capabilities are not only for semiconductor manufacturing but, increasingly, also for drive systems and precision machines that demand sub-nanometer precision for miniaturization and higher power density. The range of potential applications varies widely. As a pure displacement-sensing system, it can be used to calibrate machine tools and coordinate measuring machines. In precision mechanics and the optics industry, or in high -performance special-purpose machinery, the IDS3010 offers position counting as an alternative to incremental encoders. In a multi-channel configuration, the sensor—together with suitable actuators—works as a vibrometer to actively compensate for vibration in real-time. It can also determine mechanical eccentricity shifts due to wear or applied forces on rotating targets. For instance, the sensor can measure runout of high-speed shafts and determine its exact angular position.

Wittenstein • www.wittenstein-us.com

Leave a Reply

You must be logged in to post a comment.