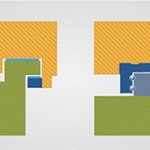

← PREVIOUS PAGE || Usually a third element — a cage — keeps the rollers well-spaced (which in turn prevents excess friction in the form of skidding or poor performance due to roller-to-roller contact).

Composite or engineered-plastic cages let rollers space more tightly together, so more rollers fit into the crossed-roller guide assembly for a given stroke length … and that in turn increases load capacity.

In contrast, cages made of aluminum or other metal take more space and reduce the guide roller count for a given length, but are often the only suitable choice for harsh environments or applications operating in cleanrooms or vacuums. That’s because composites are sensitive to contamination and can contaminate controlled environments with outgassing.

While indispensable, crossed-roller guide cages can exhibit what’s called cage creep …

Leave a Reply

You must be logged in to post a comment.