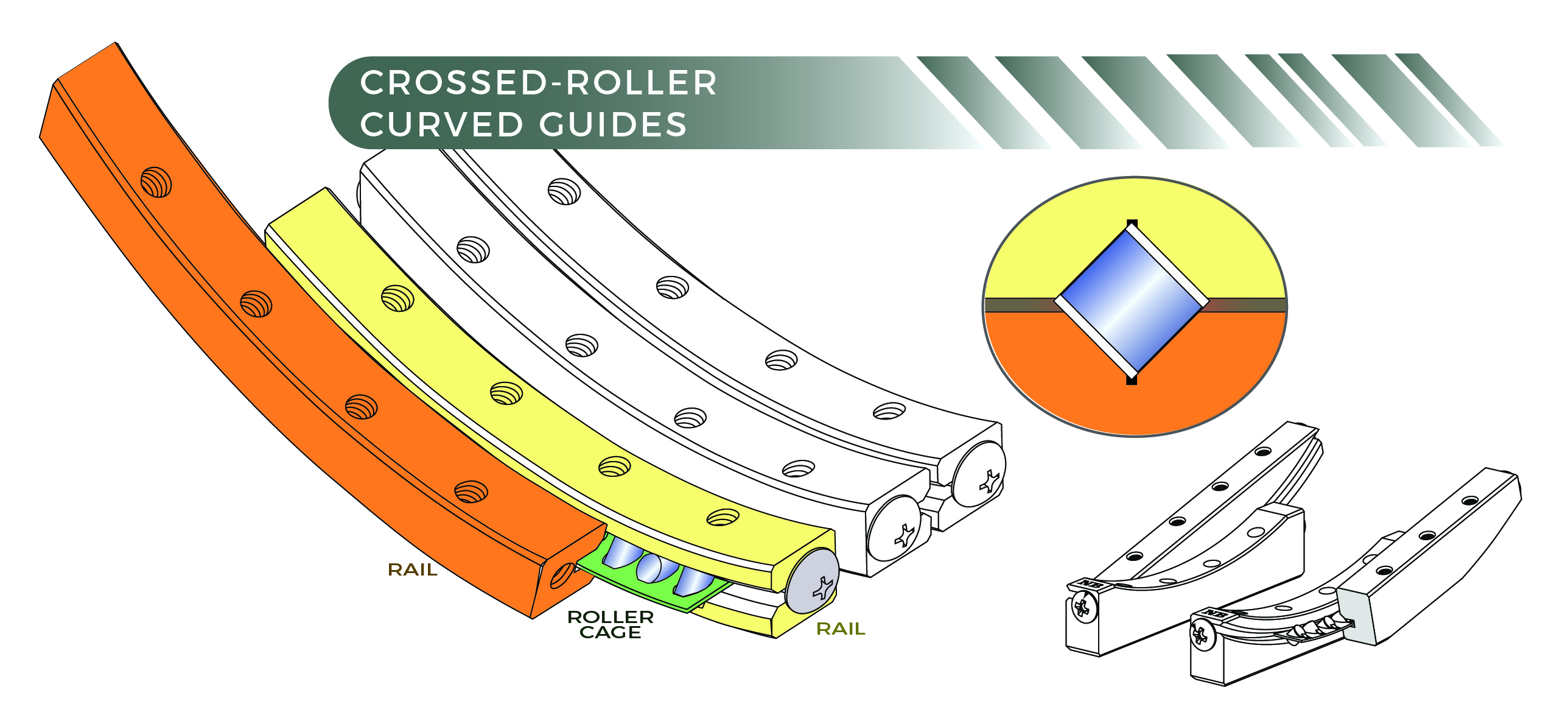

← PREVIOUS PAGE || Crossed-roller slides are often designed and assembled by component manufacturers with preload to eliminate clearance. Preload also helps minimize linear-guide deflection under load (within specified load capacities). Manufacturers’ precise machining of the top and bottom mounting surfaces ensure flatness and parallelism, though it falls to the installer to mount crossed-roller slides to suitably rigid and flat surfaces.

Applications where crossed-roller slides excel

Crossed-roller slides help boost the performance of general automation, microprocessor manufacturing, and linear axes on diagnostic equipment. As mentioned, crossed-roller guides impart high load capacity as well as high stiffness and travel accuracy — in many cases, the same applications where recirculating-roller linear guides are also suitable.

But one key advantage of crossed-roller slides over recirculating-roller linear guides that use balls is that the former maintains extremely smooth motion. The omission of roller recirculation means these precision linear guides don’t exhibit pulsations that recirculating bearings induce upon entering and exiting the internal load zones, either. That makes the guides quiet.

The high load capacity and smooth motion of crossed-roller slides often make them the leading option for short-stroke applications needing µm or nm positioning as well — such as axes in semiconductor and electronics manufacturing machinery and stages for inspection. Because there’s little difference between static and dynamic friction coefficients for crossed-roller slides, these precision rail guides also work on axes needing frequent stops and starts while executing very short strokes — as in cameras and microscopes, for example.

Leave a Reply

You must be logged in to post a comment.