Electromechanical actuators come in many varieties, with common drive mechanisms being lead screws, ball screws, and roller screws. When a designer or user wants to transition from hydraulics or pneumatics to electromechanical motion, roller screw actuators are usually the best choice. They provide comparable performance characteristics to hydraulics (high force) and pneumatics (high speed), in a less complex system.

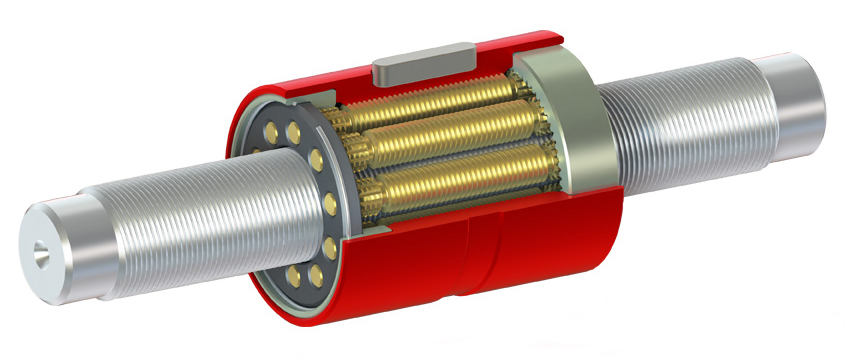

A roller screw is a type of screw drive that replaces the recirculating balls with threaded rollers. The ends of the rollers are toothed to mesh with geared rings at each end of the nut. The rollers both spin on their axes and orbit around the nut, in a planetary configuration. (This is why roller screws are also referred to as planetary roller screws.)

The nut has an internal thread that matches the screw thread. The rollers are arranged in a planetary configuration and both both spin on their axes and orbit around the nut.

The ends of the rollers are toothed to mesh with geared rings at each end of the nut, ensuring that the rollers remain in perfect alignment, parallel to the axis of the screw and nut.

Image credit: Rollvis SA

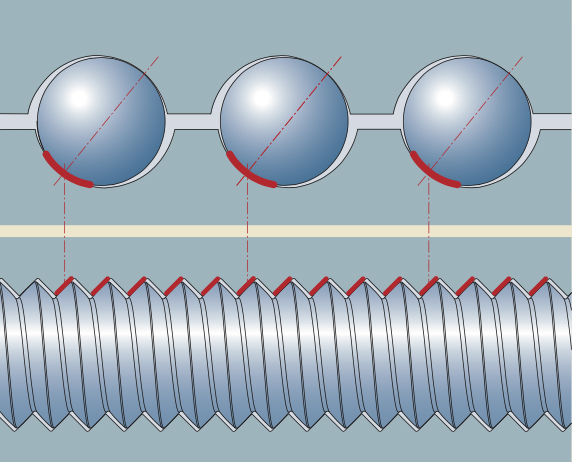

Image credit: SKF Group

The geometry of a roller screw provides significantly more contact points than are possible with a ball screw. This means that roller screws typically have higher dynamic load capacities and rigidity than similarly sized ball screws. And the fine threads (pitch) provide a higher mechanical advantage, meaning that less input torque is required for a given load.

Because their load-carrying rollers don’t contact each other, roller screws can typically travel at higher speeds than ball screws, which have to deal with the forces and heat generated by the balls colliding with each other and with the recirculation end caps.

Inverted roller screws

The inverted design works on the same principle as a standard roller screw, but the nut is essentially turned inside-out. Hence, the term “inverted roller screw.” This means that the rollers rotate around the screw (instead of the nut), and the screw is threaded only in the area where the rollers orbit. The nut, therefore, becomes the length-determining mechanism, so it is typically much longer than the nut on a standard roller screw. Either the screw or the nut can be used for the push rod, but most actuator applications use the screw for this purpose.

For a visualization of how inverted roller screws work, check out this video from SKF.

Manufacturing of an inverted roller screw presents the challenge of creating very precise internal threads for the nut over a relatively long length, which means a combination of machining methods is used. The result is that the threads are softer, and therefore, the load ratings of inverted roller screws are lower than for standard roller screws. But inverted screws have the benefit of being much more compact.

Roller-screw performance and selection

Although their load carrying mechanism differs, many attributes of planetary roller screws are similar to ball screws. They can be preloaded to reduce or eliminate backlash, by using either a split nut (in which the nut is cut transversely and a precision spacer is inserted between the front and back halves), a double nut, or oversized rollers. Roller screws are also manufactured to the same precision classes as ball screws, so lead deviation and positioning accuracy are easy to determine. And they experience the same critical speed and buckling limitations that are found with ball screws.

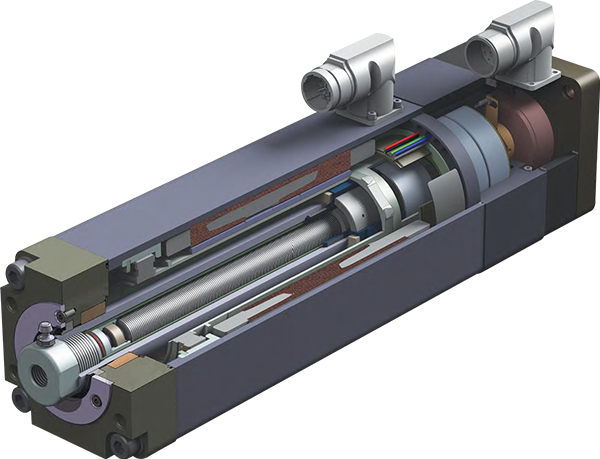

Roller screw actuators are designed with a fully enclosed housing typically made of anodized or powder coating aluminum, with special coatings or platings available to withstand corrosive environments. The force tube (also commonly referred to as a push tube or thrust tube) is made of steel, and it too can be applied with industrial powder coating for corrosion protection.

Thrust bearings on the driven end provide support for the roller screw, with a plain bushing to guide the rod as it extends in and out of the actuator. As the tube extends and retracts, it runs through a seal or wiper mounted on the end of the actuator to prevent contaminants from entering. Like many hydraulic and pneumatic cylinders, the force tube on a roller screw actuator can be provided with an internally or externally threaded rod end, a spherical eye, or a clevis end, for mounting the load.

Some roller screw actuator designs allow the force tube to rotate, which facilitates easier mounting and alignment. If the load is constrained from rotating by linear bearings or guides, this is not an issue. But if the load is not otherwise prevented from rotating, the actuator should incorporate an internal or external anti-rotation mechanism.

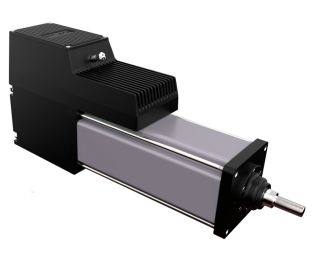

The body of a roller screw actuator makes it a fully enclosed unit, with many designs being IP rated for splash or washdown duty. This is especially beneficial since roller screw actuators are commonly used in food and packaging applications or other harsh environments. Some roller screw actuators are available with a servo motor and, in some cases, drive and control hardware and sensors integrated inside the actuator body.

Roller-screw applications

Despite the load and speed advantages of roller screws over ball screws, where roller screw actuators really make sense are cases where an electromechanical actuator is replacing a hydraulic actuator. In many instances, the desire is to move away from hydraulics to eliminate the use of hydraulic fluid, or to simplify the overall system. Roller screw actuators are the best option because they provide load capacities and stiffness characteristics similar to hydraulics. Good examples include pressing, inserting, or any application that causes high forces in the same region of the actuator’s stroke. And without the need for control components such as valves, filters, and pumps, their integration and setup are much simpler than the complex systems required by hydraulics.

For applications that require the highest level of integration possible, the motor windings can be integrated directly into the actuator body, as in this IMA model from Tolomatic.

Roller screw actuators are also used when a designer or user is seeking an alternative to pneumatic actuators. Although these applications may not require the high forces that roller screws can provide, they often involve very high speeds and acceleration rates. As a replacement for pneumatics, roller screws are often a better choice than ball screws, because roller screws can withstand frequent cycling and continuous-duty applications, conditions that can significantly reduce the life of a ball screw.

Feature image: One of the common methods for reducing backlash in a roller screw is to use a split nut design, with a precision spacer inserted between the two nut halves.

Image credit: Schaeffler Group

looking for info. about the roller screw actuator. I am looking to see if it can move in full stroke of 36in in a 1.5 seconds forward and 1.5 seconds back to home position.