Standard ball splines use balls that recirculate within a nut, or housing, similar to that of a recirculating ball linear bushing. But the mechanisms and geometry required for ball recirculation result in a spline nut that is relatively large in diameter compared to the diameter of the spline shaft.

For a more compact assembly, several manufacturers have developed a type of ball spline — referred to as a stroke ball spline or limited-stroke ball spline — that uses non-recirculating balls. By eliminating recirculation, the nut diameter of a stroke ball spline can be made much smaller than that of standard ball spline.

In a stroke ball spline, rather than recirculating elements, the spline nut uses a ball retainer that contains pockets to hold the balls and ensure they remain in their correct positions. The retainer also ensures proper spacing between the balls. With ball-to-ball contact eliminated, friction is significantly reduced and remains consistent over the entire stroke, so motion is extremely smooth and noise is greatly reduced.

Image credit: IKO

It’s important to note that because stroke ball splines are designed for low friction, seals are typically not included, so applications that include dust or contamination require that the ball spline be protected by external covers.

Because compactness is the key feature of stroke ball splines, their size range — indicated by the diameter of the spline shaft — typically runs from just 4 mm up to 16 mm. Smaller spline shaft diameters (4 and 5 mm) have two spline grooves, while larger diameter shafts typically have four grooves.

Similar to the cage in a crossed roller guide, the ball retainer in a stroke ball spline “floats” inside the cylindrical housing, or body. And because the balls don’t recirculate, the travel of a stroke ball spline is limited, with maximum stroke typically around half the overall length of the outer cylinder. And like crossed roller guides, stroke ball splines require occasional full-length strokes to re-center the retainer, as it can “creep” from its centered position, especially in vertical applications or under high-speed operation.

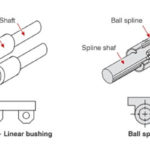

Image credit: NB Corp.

Stroke ball splines are best suited for applications such as assembly and pick-and-place, where high strokes and torque transfer capabilities are required within a very small footprint. They’re often used, for example, in electronics manufacturing.

Because accuracy is extremely important in many of the target applications for stroke ball splines, manufactures hold relatively tight tolerances for the radial runout and perpendicularity of the spline shaft and mounting surfaces, as well as for the twist, or torsion, of the spline grooves along the length of the shaft. Stroke ball splines are also commonly supplied with a small amount of preload to eliminate clearance and ensure accurate positioning in the rotary direction.

Leave a Reply

You must be logged in to post a comment.