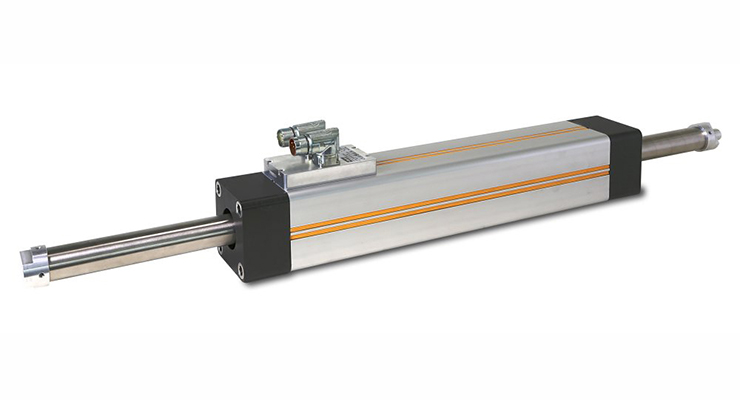

When an application requires pure thrust forces, the best type of linear actuator is often a rod-style actuator. Also referred to as thrust actuators and (when a motor is integrated) electric actuators, these electromechanical devices excel at providing axial, or thrust, forces for pushing, pulling, or holding loads. Although their function is straightforward, thrust actuators come in an extensive range of designs, sizes, and configurations.

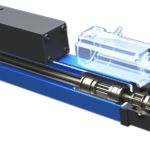

The typical drive mechanisms for thrust actuators are ball, lead, or roller screws, and tubular linear motors. Drive mechanisms that aren’t common in these designs are belt and pulley or rack and pinion systems. These drive technologies don’t have sufficient thrust force and rigidity (belts) or a suitable form factor (rack and pinion) to make sense in thrust actuator designs.

Image credit: Parker Hannifin Corp.

Thrust actuators can also be driven by pneumatic or hydraulic cylinders, but electromechanical designs are more common than air or fluid technologies in motion control applications.

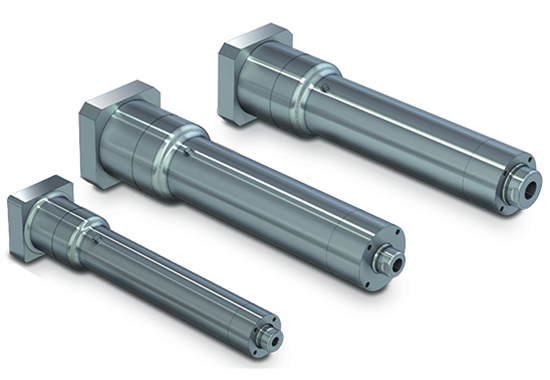

Image credit: LINAK

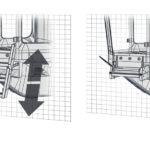

Thrust force is transmitted to the load by a rod that extends and retracts, guided by a plain bushing, from the actuator body. Typical thrust actuators don’t include linear guides, since their design is not inherent to carrying loads — only pushing, pulling, or holding them. If support or guiding of the load is required, rails, shafts, or tracks, independent of the actuator, are used.

While most rod-style actuators are designed for the housing to remain stationary and the thrust tube to extend and retract, some designs allow the tube to be fixed and the housing to move. This is more common in linear motor designs, but some screw-driven designs allow this configuration as well.

Because they often replace pneumatic or hydraulic versions, it’s common for electromechanical thrust actuators to be designed with outer dimensions and mounting options that follow standards, such as ISO and NFPA, that pneumatic and hydraulic cylinders commonly adhere to. When driven by large diameter ball screws or by roller screws, electromechanical thrust actuators have extremely high power density and provide a less complex solution than hydraulic actuators. And ball and lead screw versions are good replacements for pneumatic technologies, eliminating the need for compressors, filters, valves, and other air-handling equipment.

Electromechanical rod-style actuators are more likely than their traditional, slider-type counterparts to be provided with an integrated motor and control hardware. In addition to reducing complexity for OEMs and end users, providing a full electromechanical solution in one package makes the switch from pneumatic or hydraulic technology to electromechanical technology less cumbersome. Integration options for thrust actuators range from low-voltage DC motors with limit switches for simple end-to-end positioning, to plug-and-play servo designs with integrated motor, drive, and controller.

The housing of a thrust actuator is typically a fully-enclosed design that encapsulates the mechanical and electrical components. With a seal added to the thrust rod, it’s often possible for these actuators to achieve high IP ratings, making them ideal for applications where the actuator is exposed to fine particles, liquids, or washdown conditions. And manufacturers typically provide material options for the housing, including platings and coatings to provide corrosion-resistance to a wide range of chemicals and environments.

Leave a Reply

You must be logged in to post a comment.