Image credit: NOOK

Ball nut preload offers several benefits to screw assemblies, but the most common reason for using a preloaded ball nut is to reduce axial play, or backlash, caused by clearance between the screw and nut raceways. Reducing this axial play does two things. It improves the repeatability of the screw assembly — meaning the assembly is better able to return to the same position over repeated movements. And it increases the rigidity of the ball nut, which means the screw will experience less elastic deformation for a given load.

Despite the benefits in repeatability and rigidity, however, preload also has several potentially negative effects, particularly regarding the life of the screw assembly. The fundamental issue with adding preload to a ball nut (or any recirculating bearing) is that it produces an internal force on the nut, proportional to the amount of preload applied, and this internal force increases friction, heat, and wear.

![]()

Fpr = internal force on ball nut due to preload

Xpr = preload amount

C = dynamic load rating of ball nut

For example, if a ball nut has preload of 5 percent (Xpr = 0.05) and a dynamic load rating of 16,0000 N, the force due to preload would be 800 N.

![]()

![]()

Effective load on ball nut with preload (4-point contact)

To determine bearing life accurately, the effective load on the nut should take into account the internal force due to preload, as shown in the following equation:

Feff = effective load on the ball nut (to be used in bearing life equation)

Fa = applied external load on ball nut

Using our example above, if the applied external load is 1500 N, and the force due to preload is 800 N, the effective load on the nut is 1725 N.

![]()

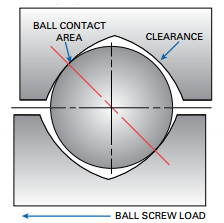

Note that the effective load equation shown above is valid for single ball nuts with preload via oversized balls, which experience 4-point contact with the raceways.

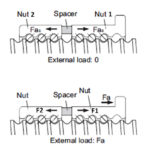

Effective load on ball nut with preload (2-point contact)

When preload is achieved via a double nut or a single nut with pitch or lead offset, which results in two-point contact between the balls and raceways, the effective load on the ball nut can be estimated with the following equation:

![]()

Given the same preload and loading conditions as above, for a preloaded nut with 2-point contact, the effective load on the nut is 1550 N:

![]()

![]()

Note that the when the preload method results in 4-point contact between the balls and raceways, there is more contact area to produce friction, heat, and wear, so fatigue will occur faster than for ball nuts with 2-point contact. Hence, the effective load on the ball nut with 4-point contact is higher than that of the ball nut with 2-point contact (1725 N > 1550 N).

When internal force due to preload (Fpr) can be disregarded

In some applications, the applied external load is sufficient to overcome the internal force due to preload. Although it might seem logical to think this would occur when the external load equals the internal force, it actually takes a significantly higher external load to negate the internal force.

When the applied external load on the ball nut equals 2.8 times the internal preload force, the preload force will be relieved and can be disregarded in the calculation of effective load.

Q: Why 2.8 times?

A: Because 2.8 represents the relationship between the maximum axial load on the ball nut and the preload force, as derived in this post.

Leave a Reply

You must be logged in to post a comment.