When a linear motion application requires high thrust force and rigidity along with good positioning accuracy, a preloaded ball screw assembly is often the best choice. Manufacturers offer ball screw preload amounts ranging from just 1 or 2 percent for applications where backlash would be detrimental, up to 10 percent or greater for applications that require very high stiffness.

While preload is beneficial for some applications, it produces additional loads that must be accounted for when sizing the screw assembly, motor, and other related components.

Methods for achieving ball screw preload

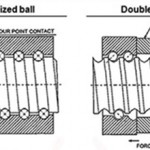

There are several ways to preload a ball screw, but the three most common methods use oversized balls in the ball nut, an adjustable-diameter ball nut, or a double nut system. Creating preload by using oversized balls allows the manufacturer to set the preload to a precise amount, although this technique is generally used for preload amounts of 5 percent or less. However, this is the most common method for preloading because it can be used with a variety of nut styles and is relatively low-cost.

Image credit: NOOK Industries, Inc.

Adjustable-diameter ball nuts allow the user to increase or reduce the preload manually, via an adjustment screw that changes the inner diameter of the nut. This method is the preferred option when the required preload may change over the life of the screw assembly – for example, to compensate for increased wear or clearance in other machine components. Although it doesn’t facilitate setting the preload to a specific level, the benefit of the adjustable nut is that if a ball nut needs to be replaced or interchanged (on the same screw), the preload of the new ball nut can easily be set to the required level.

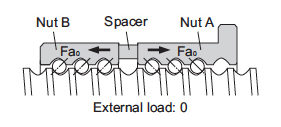

Image credit: THK

Double ball nut designs produce preload in one of two ways: through tension between two single nuts, or through an offset in the lead of a single nut. The first method uses a spring or a spacer to create tension between two nuts that are mechanically coupled. In the second method, during machining of the ball nut raceways, an offset is created in the lead, approximately halfway down the length of the nut body. This lead offset creates preload within the ball nut. Because there are no spacers or springs required, the lead offset method is more compact than a double nut design, but it reduces load capacity. With greater complexity and higher cost, double nut designs are typically used when high preload (7 percent or greater) is required.

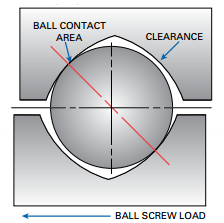

Ball screw preload reduces axial play and increases rigidity

In many applications, the primary reason for using a preloaded ball screw is to reduce internal clearance between the raceways of the nut and screw, which causes axial play (backlash). Reducing or eliminating backlash in turns improves the repeatability of the screw assembly, since there is no “lost motion” when the direction of travel is reversed. (Note that preload does not affect lead error or positioning accuracy.)

Image credit: Bosch Rexroth

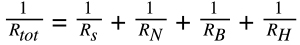

Higher preload also correlates with higher nut rigidity, which improves the rigidity of the complete screw assembly. But because the ball nut is only one component in the ball screw assembly, and its rigidity is relatively high compared to the other components, increasing the preload — from 3 percent to 5 percent, for example — has a minimal effect on the rigidity of the assembly. The most noticeable increase in rigidity of a ball screw assembly occurs when a non-preloaded ball nut is replaced with a preloaded version.

Preload also increases motor drive torque and decreases life

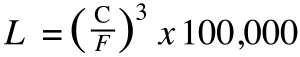

Another effect of ball screw preload is that it induces an internal load on the ball nut, which needs to be considered during sizing to ensure the motor can produce sufficient torque for the application. Preload is specified as a percentage of the ball nut’s dynamic load capacity, so in order to determine the internal load due to preload, the preload amount (0.02 for 2 percent, or 0.07 for 7 percent, for example) is multiplied by the dynamic load capacity.

The load due to preload must also be accounted for in the applied load (F) component of the bearing life equation, as shown below. Because of the cubic nature of the equation, even a small internal load due to preload can have a significant negative effect on the life of the ball screw. (Note: When the external load meets or exceeds 2.8 times the internal load due to preload, it counteracts the internal load, and the internal load can be disregarded.)

Here is a new one for me. I have play in, let’s say 0 to 90 degrees and absolutely no play for the next 270 degrees. Brand new ball screw on one side and the other side is perfect.

I have a video of it if you are interested.