Positioning stages today can satisfy specific and demanding output requirements. That’s because customized integration and the latest in motion programming now help stages get incredible accuracy and synchronization. What’s more, advances in mechanical parts and motors are helping OEMs plan for better multi-axis positioning-stage integration. Mechanical advances for stages Consider how traditional stage builds combine […]

Editor's blog

Golf-club washer uses linear-motion actuators to transport wash nozzles

Soon, you could see a new station called a Riveer TourSpin Club Washer cleaning dirty irons and hybrids at a golf course or country club near you — with the help of linear-motion actuators inside. Golf games tend to improve when players use well-maintained equipment. In contrast, dirty equipment can degrade games — not to mention golf courses […]

Motion Industries to acquire Epperson and Co.

Today, Motion Industries of Genuine Parts Co. has entered into a definitive agreement whereby Motion Industries has agreed to acquire Epperson and Co., an industrial distributor specializing in material handling products and services since 1932. Execution of the transaction is expected to take place March 1, 2016. A leading supplier of bulk material conveying products […]

PTDA Foundation Now Accepting Nominations for 2016 Wendy B. McDonald Award

The PTDA Foundation’s Wendy B. McDonald Award recognizes a woman who has established herself as a critical contributor to her company’s success and has affected positive change within the power transmission/motion control industry. More after the jump. The PTDA Foundation established the award in 2014 to honor the memory of Wendy B. McDonald, one of […]

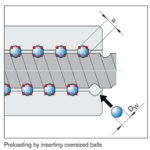

How to specify a ball screw

Ball screws are available in a range of types, styles, and sizes. A few tips, though, will help you match the right ball screw with the right application. 1. You will have the best success with specifying a ball screw if you know the following information about your application: Duty Cycle—the cycle rate, dwell times, […]

Corrosion — How bearings fail Part 3 of 6

Recently we examined how surface distress contributes to bearing failure. Now we’ll examine corrosion. Corrosion occurs primarily when either lubricants fail or the seals have failed and the bearings have been exposed to water or corrosive liquids. Corrosion can lead to early fatigue failures through the rust that forms in the bearing, especially if rust occurs in […]

Distress in bearings — How bearings fail Part 4 of 6

Recently we examined how smearing contributes to bearing failure. Now we’ll examine surface distress. Even with the best of manufacturing methods, no surface is perfectly smooth. In bearings, proper lubrication helps smooth out the roughness between bearings and raceways and other parts that interact. If the amount of lubrication is insufficient, or the lubricant is reaching the […]

Smearing — How bearings fail Part 5 of 6

Recently we examined how brinelling contributes to bearing failure. Now we’ll examine bearing smearing. Just a reminder: Factors that contribute to bearing failure include material fatigue; operating with a heavier loading than specified; inadequate or unsuitable lubrication; careless handling; poor sealing; and bearing balls or rollers installed too tightly, with insufficient internal bearing clearance. Each of these contributors leaves […]

Brinelling and why bearings fail — How bearings fail Part 6 of 6

Recently we examined how wear contributes to bearing failure. Now we’ll examine indentations, sometimes referred to as brinelling. Just a reminder, there are a number of causes that contribute to brinelling, including: • Material fatigue • Operating with a heavier loading than specified • Inadequate or unsuitable lubrication • Careless handling • Poor sealing • Bearing balls […]

Mechanical wear — How bearings fail Part 1 of 6

Today, bearing manufacturers can reliably predict the operating life of bearings, which makes it easier to specify the right bearing for an application. Bearings do fail, if for no other reason than components do not operate forever. A number of causes contribute to failure, including material fatigue; operating with a heavier loading than specified; inadequate or […]