The need to replace a linear guide in an existing machine or assembly can arise for any number of reasons: to improve the stiffness of the assembly by changing to a bearing with higher preload, or to accommodate unforeseen space constraints by using a different bearing type or style. And sometimes, a linear guide needs to be replaced […]

Plastic + composite guides

Low-cost FDA/USDA/3A dairy compliant Water Dog linear slides

FDA/USDA/3A-Dairy compliant, Water Dog Sliders from LM76 feature Corro-Slick coated 300 series stainless steel rails and contoured WDX Polymer blocks. Water Dog Sliders can be washed down with the most aggressive chemicals and caustic foaming agents and have an operating temperature range of – 400O to +180 OF. Quiet, low maintenance Water Dog Sliders can be […]

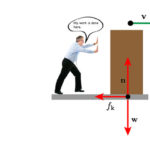

What is stick-slip?

Stick-slip, also referred to as “stiction,” is the bane of engineers and machine builders who need smooth, precise motion. Simply put, it’s the jerkiness that can plague both plain and recirculating linear bearings when they transition from standstill to motion. Here’s why stick-slip happens… When two objects slide against each other, friction works against their motion. […]

What is a PV rating?

When discussing bearing life, what comes to mind for most engineers is the standard L10 bearing life equation. But this equation was developed for bearings with rolling balls. (A similar equation exists for bearings that use rollers rather than balls.) For plain bearings, which have no rolling elements, determining the suitability of the bearing for a […]

A guide to plain bearing materials in linear motion applications

One of the benefits of plain linear bearings is their simplicity. Especially when compared to recirculating bearings, plain bearings are easy to specify, install, maintain, and replace. But don’t let that simplicity fool you. Choosing the wrong bearing, or more specifically, the wrong bearing material, can result in poor performance, degradation of the bearing, or […]

What are the differences between plain and rolling linear guides?

A linear guide (or linear bearing) is a mechanical element that allows relative motion between two surfaces, with one surface supporting the other, and minimum friction between the two. There are two basic types of linear guides: plain and rolling element. While their general function is the same, their design and performance differ significantly. Linear […]

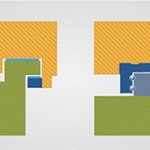

How to calculate hole spacing for joined linear guide rails

There are several reasons that a linear guide rail may be supplied in multiple sections rather than in one piece: the overall length is longer than the maximum offered by the manufacturer, the machine design or other space constraints don’t allow installation of a single piece in the length needed, or the risk of damage […]

How to calculate hole spacing for linear guide rails

Profiled linear guides—whether profiled rails, cam roller guides, shaft support rails, or plain bearing guides—are typically manufactured with evenly spaced mounting holes that allow them to be secured to a machine base or work surface. For rigidity and integrity of the rail, there’s often a minimum distance, specified by the manufacturer, that must be maintained […]